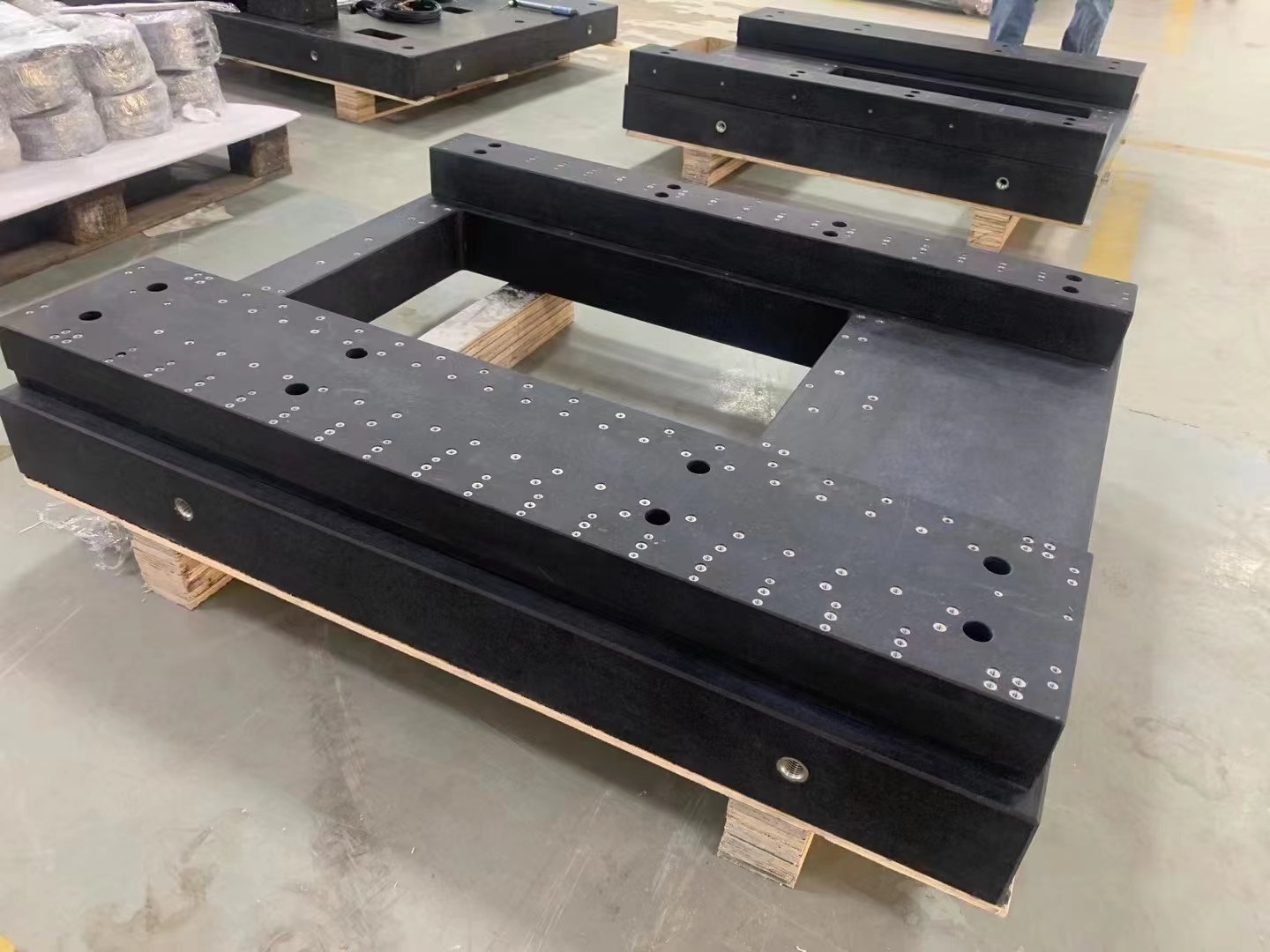

Marble platform guide base

Чудеса сварочного искусства, которые мы создаем вместе

ДЕТАЛИ ПРОДУКЦИИ

Требования к установке линейных направляющих на мраморных платформах

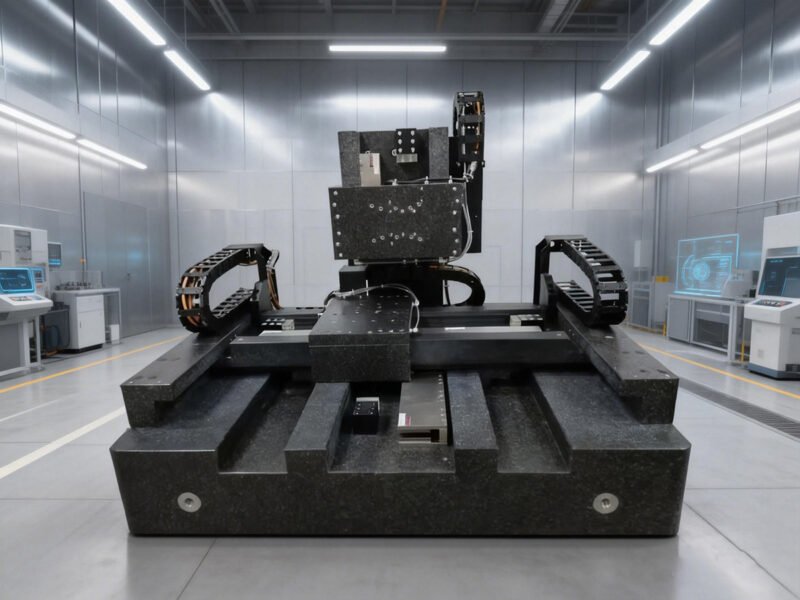

In the process of industrial production, marble platforms are type of high-precision measuring reference surface, and their unique physical characteristics give them significant advantages in the field of precision measurement.

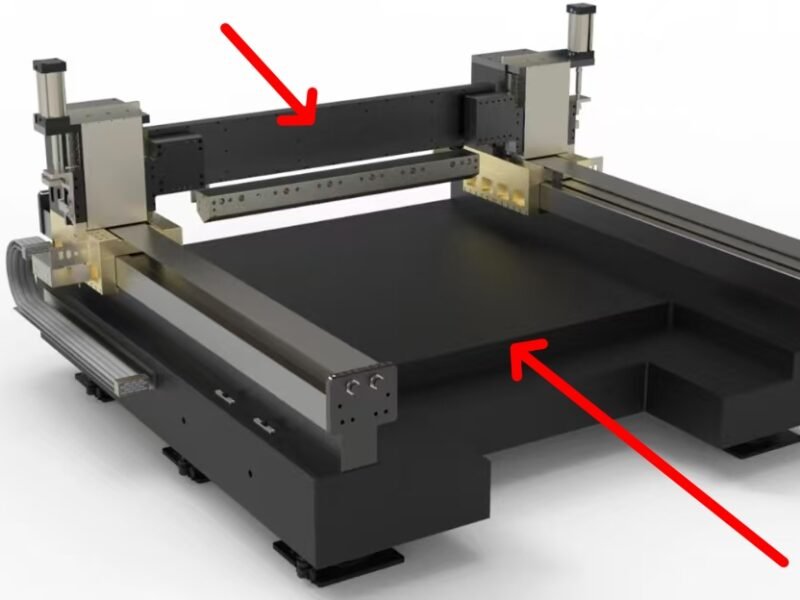

In some industries, it is necessary to install guides marble, mainly divided into two categories: one is to drill holes on the marble platform and install guides to test the straightness and flatness of products. The second category is to guides on non-standard marble components to achieve the purpose of component design. So, what are the precautions when they install guides?

Precautions for Installing Guides

1 Keep the marble platform (the area where the guide is installed) clean and tidy. When cleaning, pour alcohol on a dust-free cloth and wipe the flat surface. After wip clean, use a dry and clean hand to lightly drag it on the surface of the platform. If there is a feeling of blockage, it needs to be scraped with a; if it is smooth and unobstructed, then the first step is completed.

- Take out the guide (wear rubber gloves to prevent the guide from rusting, use a dust-free cloth alcohol to wipe the guide installation surface, and remove the guide oil. After cleaning, place the guide in the installation area of the marble platform align the hole positions.

- Align the hole positions of the guide and the marble installation holes, place the marble level next to the guide (the distance should be close not far), and make it roughly parallel to the guide. If the marble has an installation reference surface, the marble level can be omitted, and the reference surface of the marble or component itself can be used to adjust the guide.

- Fix the first hole position of the guide, leaving room for adjustment up, down, left, and right. a magnetic dial indicator lever indicator (it is not recommended to use other types of indicators) on the guide slide block, and then adjust the marble level to ensure the installation of the guide (if there are any questions, please consult our professional personnel).

- Straighten the guide.

By this point, the guide installation is fully completed It should be noted that in this state, there is no problem using this guide to measure the relative straightness of the workpiece, but it is not accurate to measure the flat of the workpiece in the up-down direction. This is because there is an error in the Y-shaped undulation of the guide itself, and the walking parallelism after should be confirmed with the guide manufacturer. If the guide is selected as an ultra-precision imported guide, its walking parallelism is sufficiently small, and this method can also be used measure the flatness of the workpiece.