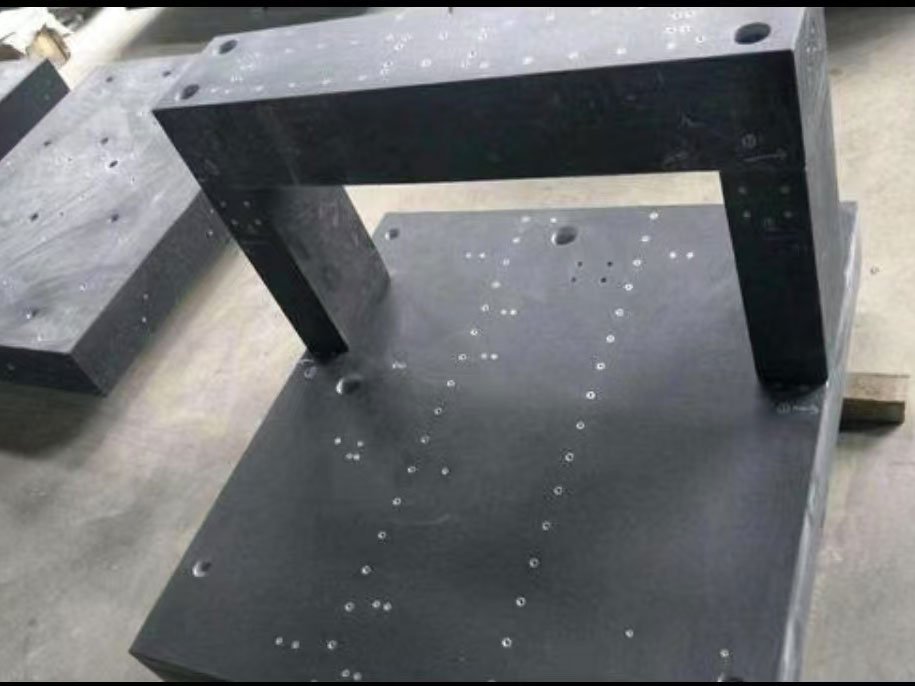

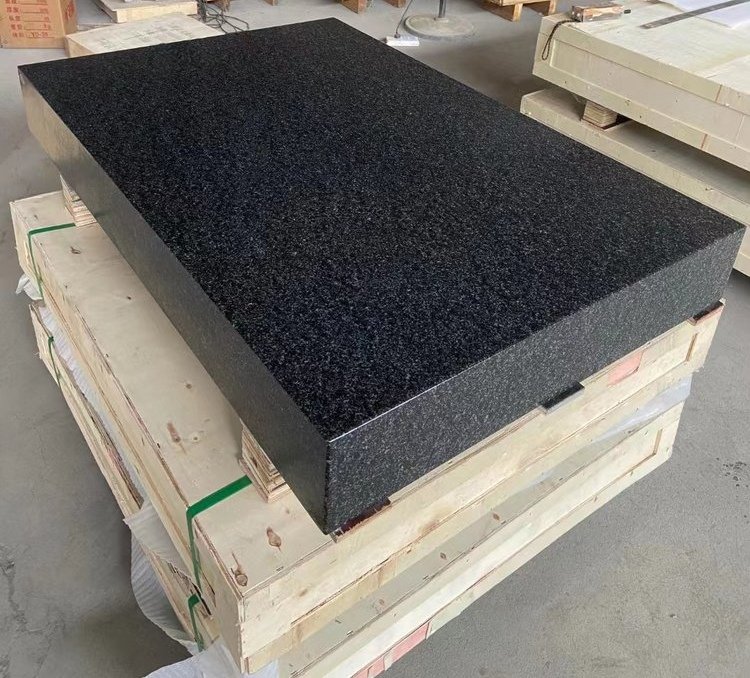

Precautions for granite precision components assembly:

During the assembly process, whether it is cast iron parts or marble components, stone or other materials, there are many key points that need to be followed collectively to comply with the contract. It is not allowed to assemble arbitrarily. To ensure the quality of the assembly of stone machinery products, it is necessary to operate according to the various technical requirements for the assembly of stone machinery products. Although the technical requirements for the assembly of different stone machinery products are not exactly the same.

1. It is necessary to do a good job of part cleaning and cleaning. Cleaning work includes removing residual casting sand, rust, chips, etc. Especially for some important parts, such as gantry cutters, inner cavities should be coated with rust-proof paint. Diesel, kerosene, or gasoline can be used as cleaning agents to clean oil stains, rust, or chips attached to parts, and then blow dry with compressed air.

2. Lubricant should be added to the mating surface before fitting or connecting. Especially for bearings in spindle boxes and screw nut parts of lifting mechanisms.

3. The dimensions of the mating parts should be accurate, and the dimensions of the mating parts should be rechecked or spot checked during assembly. For example: the shaft journal of the spindle and the mating part of the bearing, the hole and its center distance that the spindle box cooperates with the bearing.

4. The assembly of the wheel requires that the axes of the two meshing wheels are in the same plane and parallel to each other, and there should be a normal meshing clearance, and the axial misalignment ≤ 2MM.

5. The joint surface of the connection should be checked whether it is flat and whether there is deformation. Otherwise, it should be repaired, burrs removed, and the joint surface is in close contact, flat, and not skewed.

6. The sealing parts should be pressed into the sealing groove parallel and should not be twisted or deformed, and the sealing surface should not be damaged or scratched.

7. The assembly requirements for the belt pulley are that the two belt pulley axes are parallel, and the center of the pulley groove should be positive, and a large offset will cause the belt pulley tension to be uneven, causing the belt to slip and accelerate wear. At the same time, the V-belt should be selected before assembly, and the length should be consistent to prevent vibration during transmission.

8. Bearings should be cleaned before assembly, and can only be assembled after the rust-proof paint is removed; when cleaning, it is necessary to check whether the raceway and rolling elements are rusted, and whether the rotation is flexible; when assembling bearings, it is necessary to apply a layer of lubricating oil on the surface of the mating parts, and if a large pressure difference is found during assembly, it should stop assembly and check; when assembling bearings, the end without the model should face inward, towards the shoulder of the shaft; when inserting bearings, the direction and position of the force should be appropriate, and the raceway and rolling elements should not be stressed, it should be knocked symmetrically and evenly, not violently, and the end face should be perpendicular to the shaft to prevent installation from tilting.

Not only granite machinery equipment base need to be assembled with special attention, but also surface plate , marble right-angle rulers, marble square boxes, marble levels, etc