Marble platforms are made from high-quality rock layers underground, which have been naturally aged for hundreds of millions of, making their shape extremely stable. There is no need to worry about deformation due to normal temperature differences. Granite materials that have undergone strict physical tests and selection have dense crystals, texture, and a compressive strength of 2290-3750 kg/cm², with a hardness of 6-7 on the Mohs scale They are extremely wear-resistant, acid-resistant, alkali-resistant, and have high corrosion resistance, and will never rust. Since marble is a non-metallic material it has no magnetic reaction and no plastic deformation. Its hardness is 2-3 times higher than cast iron (equivalent to HRC>51), so it has good retention. In use, even if the rock tool is knocked by a heavy object, it will only lose a few pieces of stone chips at most, unlike metal tools, which will damaged by deformation and affect precision. It is superior to precision measurement benchmark parts made of high-quality cast iron and steel, and can achieve high and stable precision.

Marble platforms require marble stone material, which is found in Shandong and Inner Mongolia. Among them, the material in Shandong is the best and the material in Inner Mongolia cannot compare with that in Shandong. The main production bases of marble platforms are concentrated in Bocheng City and Gaotang County inandong.

Преимущества

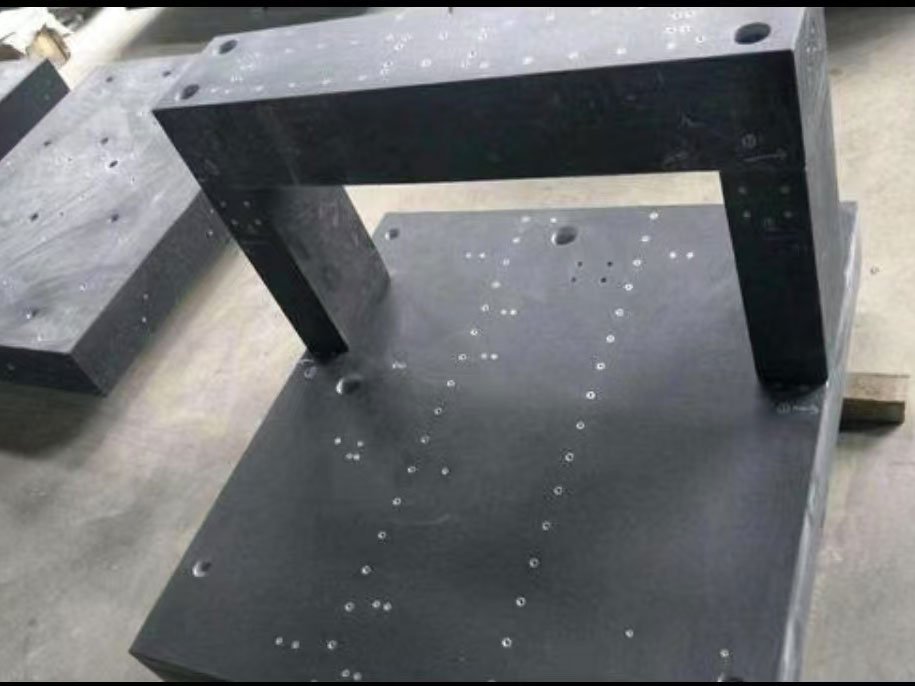

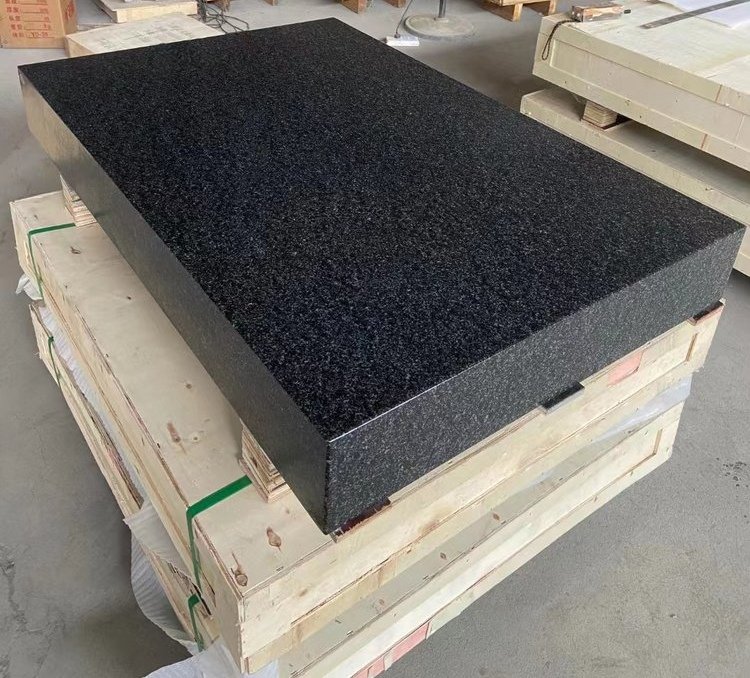

Marble platforms are made of high-quality natural marble after mechanical processing and manual fine grinding. They have a black gloss, precise structure uniform texture, and good stability. They are strong, hard, and have the advantages of being rust-proof, acid-resistant, alkali-resistant, non-magnetic,-deformable, and wear-resistant. They can maintain stability under heavy loads and normal temperatures.

Marble platforms are precision benchmark measuring tools made of natural stone materials They are ideal for the inspection of instruments, precision tools, and mechanical parts. Especially for high-precision measurements, its unique characteristics make cast iron plates look inferior.

Gite slabs, precision granite slabs, granite inspection slabs, and instrument platforms are made of high-quality “Jinan Blue” stone after mechanical processing and manual fine. They have a black gloss, precise structure, uniform texture, and good stability. They are strong, hard, and can maintain high precision under heavy loads and normal temperatures. also have the advantages of being rust-proof, acid-resistant, alkali-resistant, wear-resistant, non-magnetic, and non-deformable. Granite sl are suitable for measuring tools in machine factories.

Характеристики

The main features of marble platforms are stable precision and easy maintenance. This is because:

①The marble platform has a structure, a smooth and wear-resistant surface, and a small roughness value;

②After long-term natural aging, the internal stress completely disappears, the material is stable and it will not deform;

③Withstands acid, alkali, corrosion, and magnetic resistance;

④Will not rust when damp, easy use and maintain;

⑤The linear expansion coefficient is small, and the influence of temperature is small;

⑥After the working surface is collided or scratched, dents will be produced, not burrs or splinters, which will not affect the measurement accuracy.

The main disadvantage of rock slabs is that they cannot withstand excessive or knocking, and they will deform at high humidity, with a moisture absorption of 1%. Requirements for the working surface of the marble platform:

The marble platform shall free of defects such as sand holes, shrinkage, scratches, dents, pores, cracks, inclusions, and rust that seriously affect the appearance and performance on the working surface Minor depressions or missing corners on the non-working surface of the marble platform are allowed to be repaired.

Flatness and specific gravity

Flatness according to: GB4987-85 standard: 00 grade = 2 × (1 d/1000) um

0 grade 4 × (1 d/1000) um 1 grade = 8 × (1 d/1000)

Material Introduction

The main mineral components are pyroxene, plagioclase, a small amount of oliv, biotite, and a trace amount of magnetite, with a black color, precise structure, and uniform texture after millions of years of aging, with good stability, high, and high hardness, and can maintain high precision under heavy load. It is suitable for measurement work in industrial production and laboratories.

Development Potential

The main characteristics of marble are stable precision and convenient maintenance. This is because: the marble slab has a tight organizational structure, a smooth and wear-resistant surface, and a small roughness value;

ble has completely disappeared internal stress after long-term natural aging, and the material is not chaotic and will not deform; resistant to acid, alkali, corrosion, and magnetic; will not rust due to dampness, and it is convenient to use and maintain; the linear expansion coefficient is small, and it is less affected by temperature; after the working surface collided or scratched, it will only produce pits, not produce convex lines, burrs, and has no effect on the measurement accuracy. The main disadvantage of marble platforms is they cannot withstand excessive impacts and knocking, and they will deform at high humidity. The water absorption is 1%.

Marble platforms are made of high-quality marble layers, which have been naturally aged for hundreds of millions of years, with extremely stable shapes, and there is no need to worry about deformation due to normal temperature differences. The granite selected through strict physical tests have fine crystallization, hard texture, and compressive strength of 2290-3750 kg/square centimeter, with a of 6-7 on the Mohs scale. (Shaw hardness SH70 or above) extremely wear-resistant, acid-resistant, alkali-resistant, and has high corrosion resistance, and will never rust. Since granite is a non-metallic material, there is no magnetic reaction, nor plastic deformation. Its hardness is 2-3 higher than cast iron (equivalent to HRC>51), so it has good precision retention. According to national standards, the precision grade can be divided into 00, 00, 0, and 1 grades.

Marble platforms are precision reference measuring tools made of natural stone materials. They are ideal reference surfaces for the inspection precision instruments, precision tools, and mechanical parts. Especially for high-precision measurement, due to its unique characteristics, it makes cast iron slabs look inferior