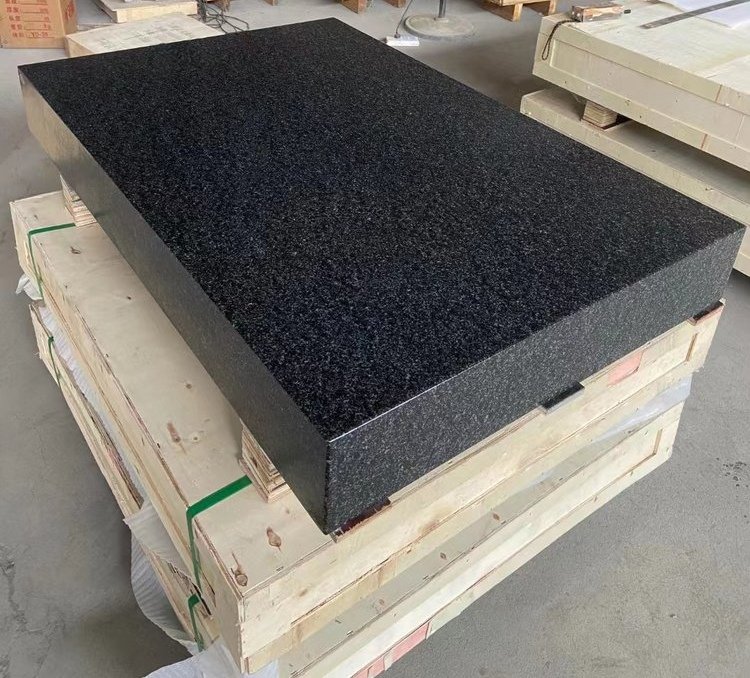

Grinding process steps for granite precision mechanical platform 1. Pre-treatment: Check the appearance of the granite platform that been roughly processed, remove surface cracks, sand holes and other defects, then clean the surface dust and oil stains, and let it dry for later use. 2. Cl and positioning: Use vacuum suction cups or special clamping fixtures to fix the platform, ensure that the clamping is firm and the force is uniform, and prevent the platform from or deforming during grinding. 3. Rough grinding: Select the coarse grinding disc with diamond resin bond, match with oil grinding fluid, set the appropriate grinding pressure (gener 0.1-0.3MPa) and grinding disc speed (20-40r/min), remove the traces of rough machining on the surface the workpiece, and reduce the surface roughness of the platform to Ra0.4μm. 4. Semi-fine grinding: Replace the diamond grinding disc with particles, adjust the grinding pressure to 0.05-0.1MPa, reduce the grinding disc speed, further refine the surface texture, optimize the roughness to0.1μm, and correct the flatness error of the platform. 5. Fine grinding: Use ultra-fine diamond grinding paste or soft grinding tools, match water-soluble grinding fluid, and use low pressure (0.02-0.05MPa) and low speed grinding method to achieve mirror surface processing, so the roughness reaches Ra0.025μm below, to meet the accuracy requirements of the precision mechanical platform. 6. Cleaning and detection: After grinding, the residual grinding fluid and grinding chips on the surface of the platform with anhydrous ethanol or special cleaning agent, and then use precision instruments such as level and interferometer to detect key such as flatness and parallelism, and put them into the warehouse after passing the test.