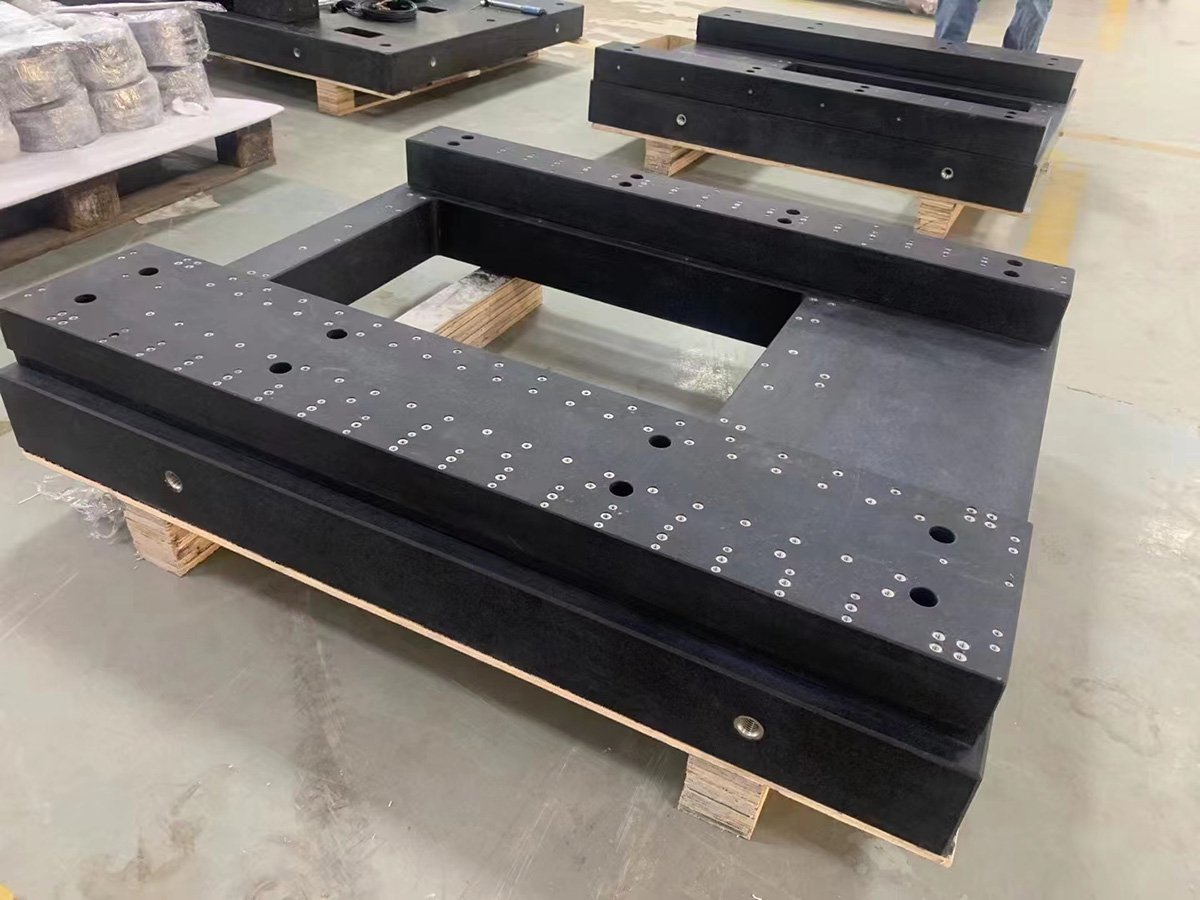

Base de máquina de granito

Welding Wonders Forjando juntos la excelencia

DETALLE DE PRODUCTOS

🎯 Core Advantages

The advantages of granite mainly stem from its natural and stable physical properties:

· Longterm precision and stability

· Characteristics: After billions of years of natural aging, the internal stress of the rock has been eliminated, and it hardly deforms. The of thermal expansion is extremely small, and it is insensitive to temperature changes.

· Advantages brought: It can maintain a working precision of microns or even higher for a time (for example, the flatness can reach 2 microns), making it an ideal reference measuring surface and equipment base.

· Excellent physical and chemical properties

Characteristics: High hardness, wear resistance; non-conductive, non-magnetic; resistant to acid and alkali corrosion.

· Advantages brought: Long service life suitable for electromagnetic sensitive environments; no need for oiling to prevent rust, simple maintenance.

· Excellent damping and shock-absorbing properties

· Characteristics: The internal structure can effectively absorb and attenuate vibrations.

· Advantages brought: Significantly reduce the vibration of the equipment itself and external interference, and improve the stability of precisionining and measurement.

🛠️ Main Application Fields

Based on the above advantages, granite components play a central role in many high-precision and cutting-edge fields:

· Precision measuring instruments

· Typical equipment: Workbench, guide rail, and beam of the three-coordinate measuring machine; various granite plates, straightedges, and gauges, etc., as reference measuring tools.

· Role: As a geometric reference for measurement, its stability directly determines the measurement accuracy of the instrument.

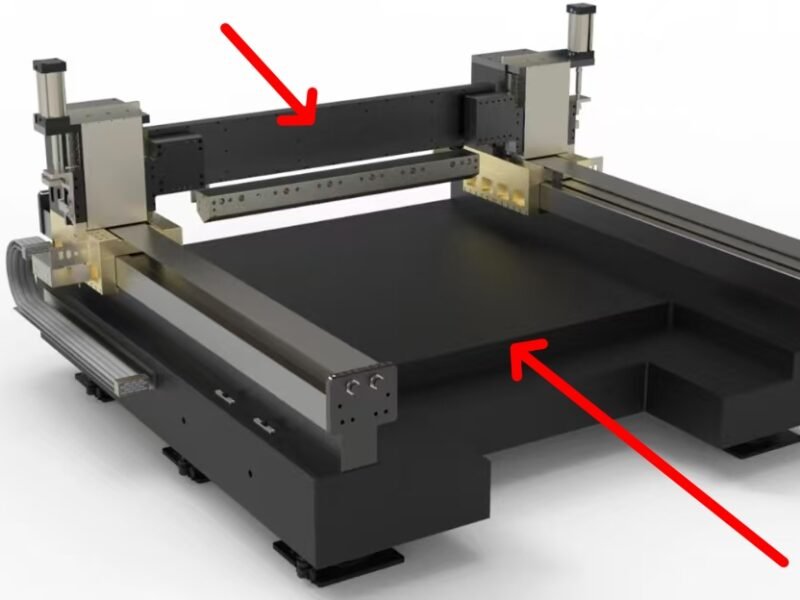

·-end manufacturing and testing equipment

· Typical equipment: Base and workbench of high-precision CNC machining centers, laser equipment, and optical equipment; frame of optical inspection equipment.

· Role: Provide a super stable and vibration-resistant “foundation” for the equipment, ensuring that the machining and testing processes are not.

· Semiconductor and electronic industries

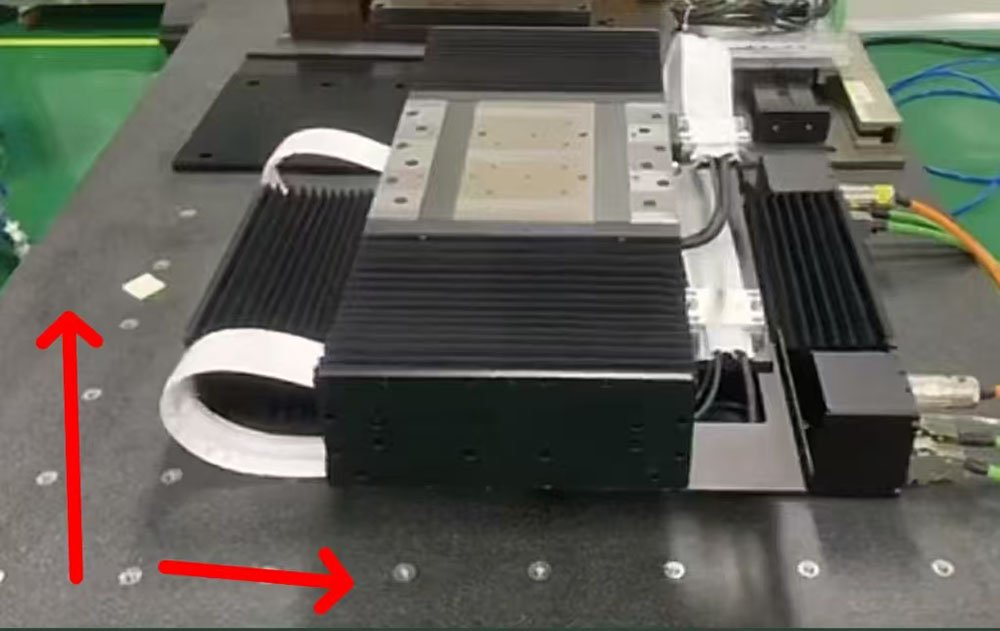

· Typical equipment: Wafer air-floating platform, precision positioning platform, PCB drilling machine body.

Role: In a cleanroom environment, its dust-free, low thermal expansion, and highly stable characteristics are key to ensuring nanometer-level process precision.

· Other precision

· Typical equipment: Precision motion truss systems that require ultra-high repeat positioning accuracy (such as below 6 microns).

· Role: Used high-rigidity and high-damping mechanical structural components to improve the dynamic performance of the system.