Keywords: Granite surface plate manufacturing, diamond grinding, vibration aging, automation

The production of granite surface plates involves rigorous multi-stage processes:

- Raw Material Selection: Blocks are sourced from quarries with consistent mineral composition (typically 60-70% quartz, 15-20% feldspar, and <10% mica).

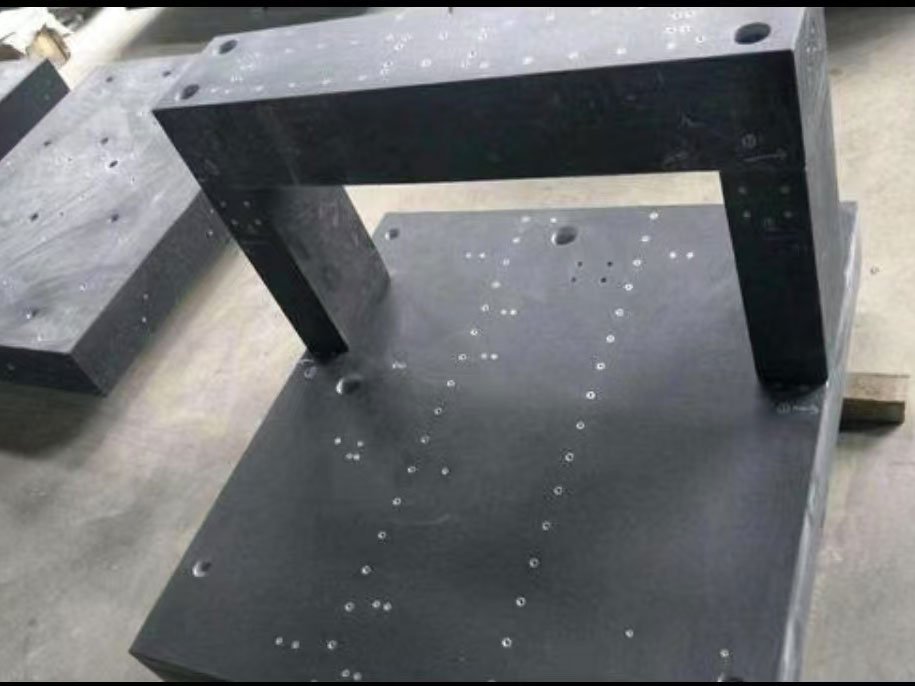

- Coarse Shaping: Computer-controlled saws cut blanks to near-final dimensions, minimizing material waste.

- Precision Grinding: Diamond-impregnated wheels refine surfaces to micrometer-level tolerances. Automated systems employ laser interferometry for real-time flatness monitoring.

- Vibration Aging Treatment: Post-grinding stress relief using resonant frequency vibration ensures long-term stability.

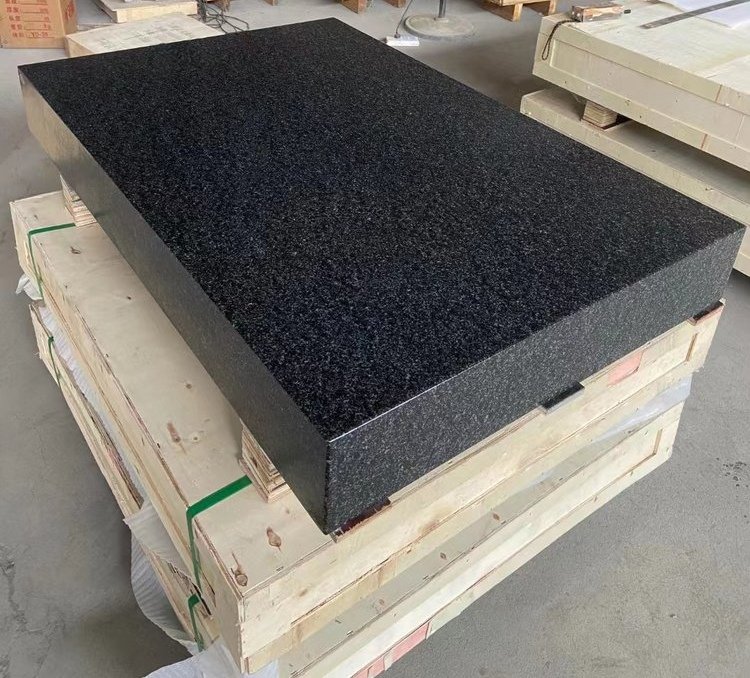

- Final Lapping: Nano-abrasive slurries achieve mirror finishes (Ra < 0.2μm) critical for optical measurement applications.

Advanced facilities utilize robotic handling and AI-driven quality control, reducing human error. For instance, Botou Jingda’s automated line achieves 98% first-pass yield for Grade 00 plates.