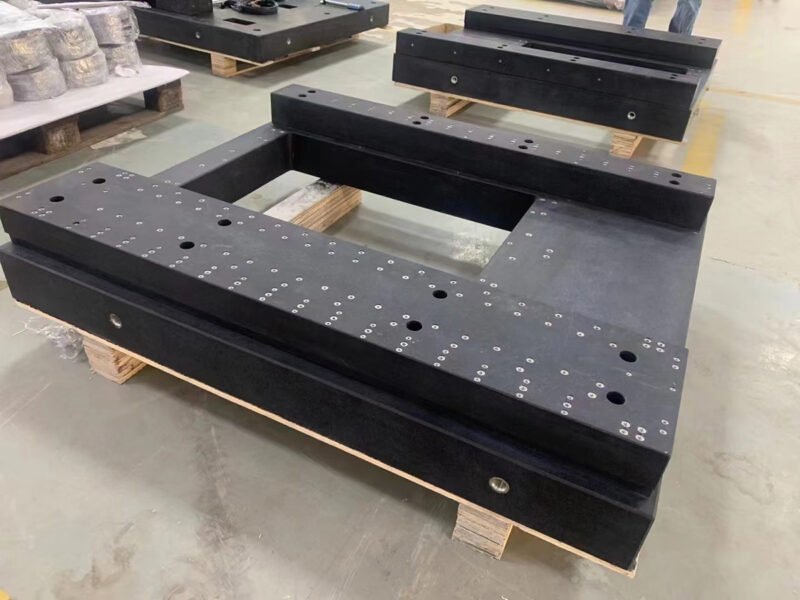

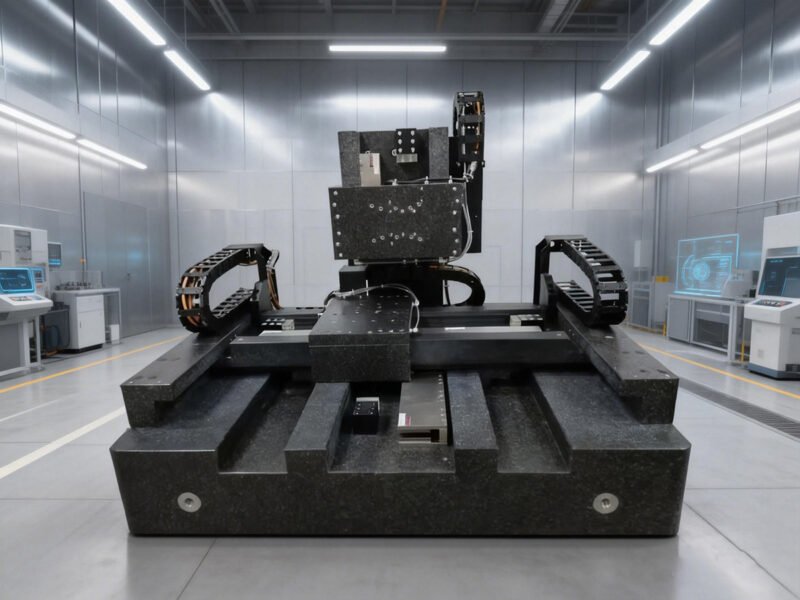

Granite machinery equipment base

Welding Wonders Forging Excellence Together

PRODUCTS DETAIL

Precision granite components are made of high-quality Jinan green stone, which is processed by machinery and finely ground by hand. It has high precision, no deformation, good and long service life.

Our company can process various granite base columns, beams, guide rails and other accessories for CMM for users.

Our company can process various printed circuit board drilling, milling machine, engraving machine granite base, gantry, slide plate and other accessories for users.

Technical Parameter Comparison Table: Granite Platform vs. Traditional Metal Platform for CMM

| Technical Parameter | Granite Platform | Traditional Metal Platform (Cast Iron/Steel) | Core Advantages |

| Coefficient of Linear Expansion | (8~9)×10⁻⁶/℃ | (11~12)×10⁻⁶/℃ | Minimal impact from ambient temperature fluctuations, ensuring long-term measurement accuracy stability |

| Flatness Tolerance | Grade 00: ≤2μm/m; Grade 0: ≤5μm/m | Grade 00: ≤8μm/m; Grade 0: ≤12μm/m | Higher reference surface flatness, providing precise support for CMM measurements |

| Rigidity Modulus | Approximately 90~100GPa | Approximately 70~80GPa | High rigidity against deformation, no warping after loading workpieces, ensuring measurement accuracy |

| Wear Resistance | Dense natural structure, high wear resistance | Prone to wear, surface accuracy declines after long-term use | Longer service life, reducing costs of frequent maintenance and precision calibration |

| Magnetic Resistance / Conductivity | Non-magnetic, non-conductive | Magnetic, highly conductive | Avoids interfering with CMM probe signals, suitable for high-precision testing scenarios |

| Corrosion Resistance | Acid and alkali resistant, no rusting | Prone to oxidation and rusting, requiring regular anti-rust treatment | Adapts to complex workshop environments, reducing maintenance frequency |