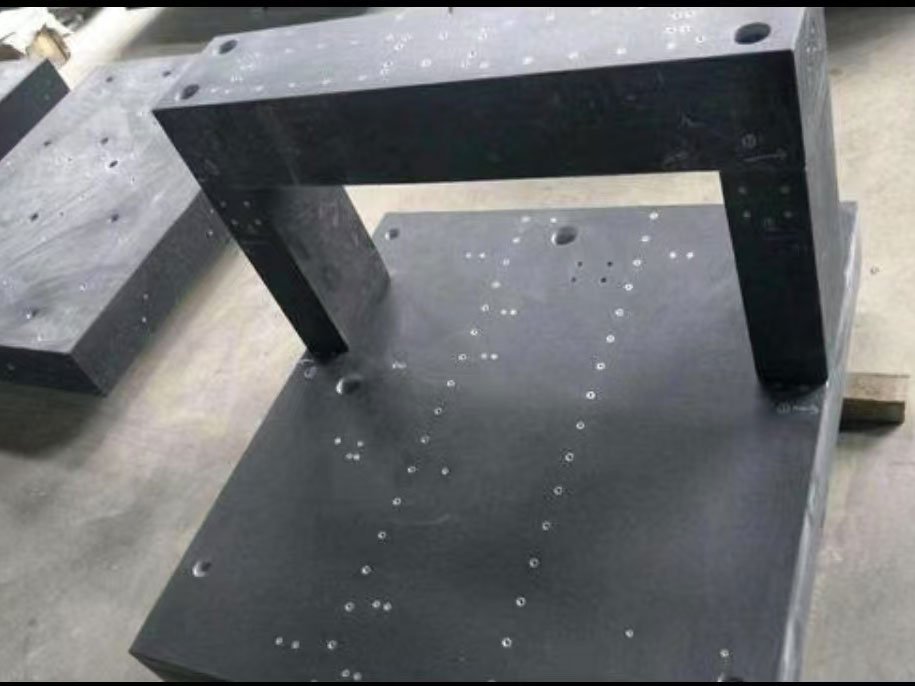

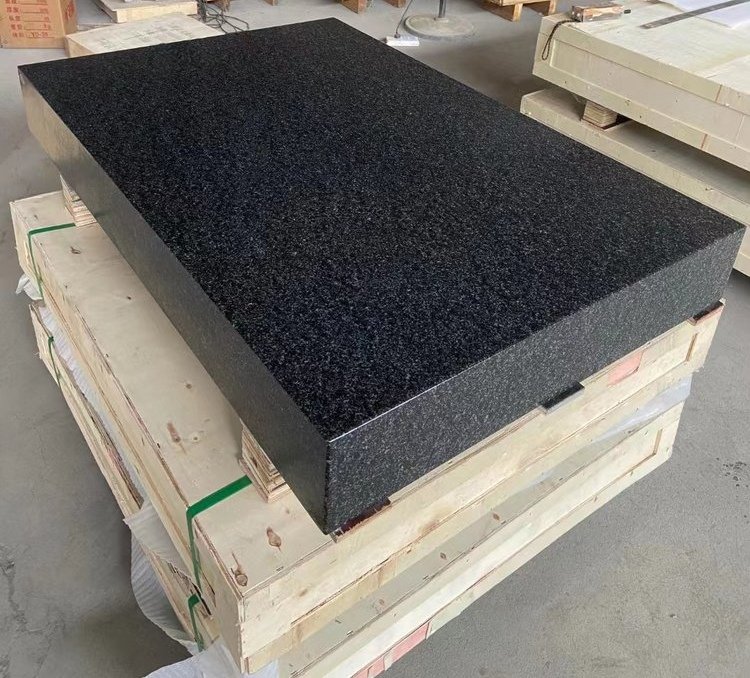

Granite platforms serve as the core base/working table of Coordinate Measuring Machines, and their application characteristics are centered on the stability and precision retention required for high-precision measurement, perfectly adapting to the stringent accuracy demands of CMMs. The key application characteristics are as follows: 1. High rigidity with minimal deformationGranite features a dense texture and high elastic modulus, resulting in negligible deformation even under the load of the CMM body and measured workpieces. This avoids measurement accuracy errors caused by base deformation, meeting the strict rigidity requirements of CMMs for their foundation.2. Superior inherent flatnessAfter precision grinding and scraping, granite platforms can achieve ultra-high accuracy in flatness and straightness. They provide a precise datum plane for the probe movement and workpiece positioning of CMMs, ensuring the accuracy of the measurement benchmark.3. Excellent thermal stabilityWith a thermal expansion coefficient much lower than that of metals (e.g., cast iron), granite is barely affected by ambient temperature changes. In conventional measurement environments such as workshops and laboratories, it effectively reduces measurement errors caused by temperature drift, suitable for the high-precision detection scenarios of CMMs.4. High wear resistance and long-term precision retentionBoasting a high surface hardness (Mohs hardness 6-7), granite is resistant to scratches and wear. Its core precision indicators such as flatness remain stable after long-term use, eliminating the need for frequent recalibration and reducing the maintenance costs of CMMs.5. Magnetic resistance and corrosion protectionNon-metallic and non-magnetic, granite will not cause magnetic interference to the electromagnetic probes and precision sensors of CMMs. Meanwhile, it is resistant to acids, alkalis and corrosion, requiring no additional rust-proof treatment in industrial environments and adapting to various detection working conditions.6. Outstanding vibration absorptionNatural granite has good damping properties, which can effectively absorb vibrations generated during CMM operation and external seismic sources in the workshop environment. This reduces the interference of vibration on probe detection and ensures the stability of measurement data.7. Low maintenance and easy cleaningThe dense, non-porous surface of granite is not prone to oil stain and dust adhesion. Daily cleaning only requires simple wiping, and no rust-proof painting or other maintenance is needed unlike metal bases, adapting to the efficient daily use of CMMs.