Las herramientas de medición de granito han demostrado ventajas significativas en el campo de la medición de precisión debido a sus propiedades materiales únicas. A continuación se exponen sus principales ventajas y análisis específicos:

- High precision and long-term stability

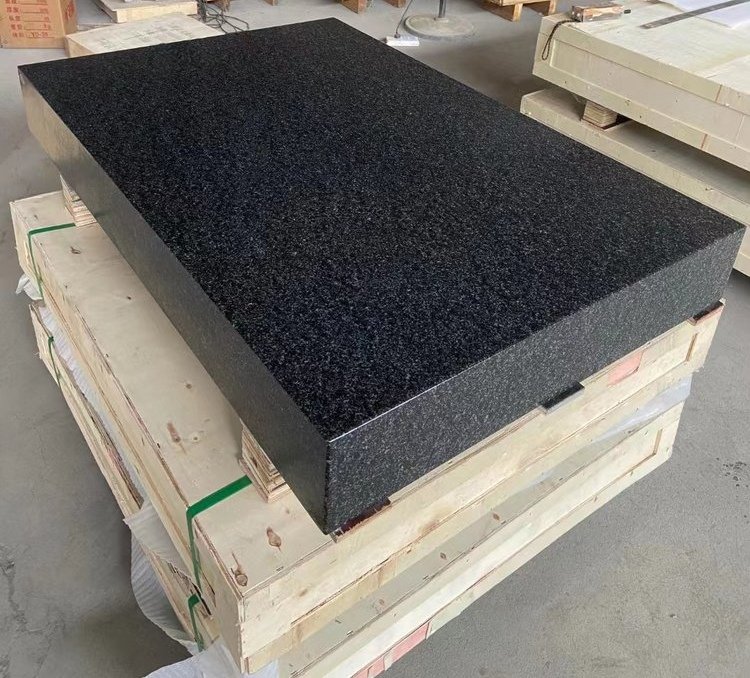

Micron level machining accuracy:

After mechanical processing and manual precision grinding, the flatness error of granite can be controlled within ± 0.01 millimeters (00 level accuracy), and the surface roughness can be as low as Ra 0.32 μ m, meeting the ultra precision measurement requirements in aerospace, optical instruments and other fields.

Extremely low deformation rate:

The coefficient of linear expansion is only 4.6 × 10 ⁻⁶/℃, comparable to indium steel, and is minimally affected by temperature fluctuations. Under a temperature difference of ± 2 ℃/24h, the deformation can be ignored to ensure long-term reliability of the measurement results.

Complete stress release:

After billions of years of natural aging treatment, the residual stress inside has completely disappeared, the organizational structure is dense and uniform, and it does not deform after long-term use. The accuracy retention far exceeds that of metal measuring tools. - Excellent environmental resistance performance

Strong corrosion resistance:

Chemical stability, acid and alkali corrosion resistance, no rust, no need for oil maintenance. Under harsh conditions such as chemical workshops and marine environments, it can still maintain a smooth surface and measurement accuracy, with a service life of several decades.

Anti magnetic interference:

As a non-metallic material, it has no magnetization reaction and can avoid measurement errors caused by magnetization in metal measuring tools. It is suitable for scenarios such as electronic component detection and magnetic material processing that require isolation of electromagnetic fields.

Electrical insulation:

The non-conductive property makes it safe and reliable in high voltage or electrostatic sensitive environments, avoiding measurement results affected by current interference. - Durability and low maintenance cost

High hardness and wear resistance:

The Mohs hardness reaches 6.5, the wear resistance is 5 times that of cast iron, and the surface has strong scratch resistance after grinding, making it suitable for long-term use in heavy load environments.

Low water absorption rate:

The water absorption rate is only 0.13%, making it difficult to adhere to dust or liquids, easy to clean, and surface scratches or slight bumps do not affect the overall flatness, resulting in low maintenance costs.

Aging resistance:

UV resistance, strong weather resistance, not easy to age and crack in outdoor or high temperature environments, and strong adaptability. - Structural uniformity and seismic resistance

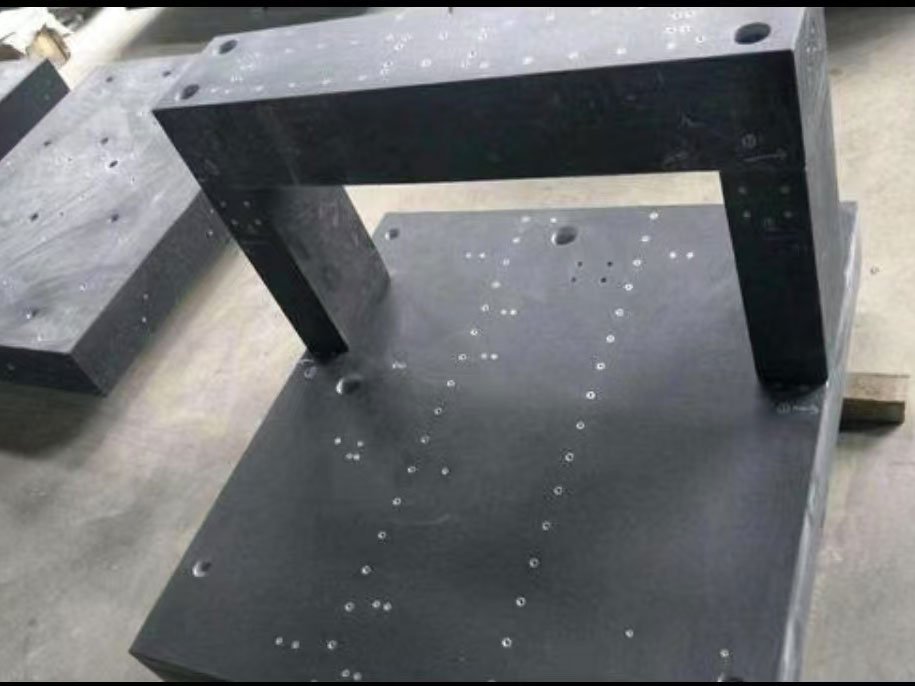

Dense crystal structure:

Formed by the uniform distribution of minerals such as feldspar and quartz, without internal defects, it has better impact resistance than cast iron and is suitable for industrial scenarios with high vibration.

Shock absorption performance:

The natural damping characteristics can effectively absorb vibration energy, reduce errors caused by equipment vibration during the measurement process, and improve data stability. - Environmental Protection and Safety

Non toxic and harmless:

Granite is a natural inorganic material that does not contain harmful substances and meets environmental protection requirements. It is suitable for clean room environments in industries such as food and medicine.

Fire and explosion prevention:

The non combustible and non explosive characteristics make it safe and reliable in high temperature or flammable and explosive environments, reducing the risk of accidents. - Economy and Applicability

Long term low cost:

Although the initial procurement cost is higher than that of ordinary metal measuring tools, due to their long lifespan, less maintenance, and lower overall cost, they are particularly suitable for high-frequency usage scenarios.

Suitable for multiple scenarios:

It can be processed into various types such as inspection platforms, square rulers, square rulers, and flat rulers to meet the measurement needs of different industries, such as machine tool calibration, mold testing, scientific research experiments, etc.