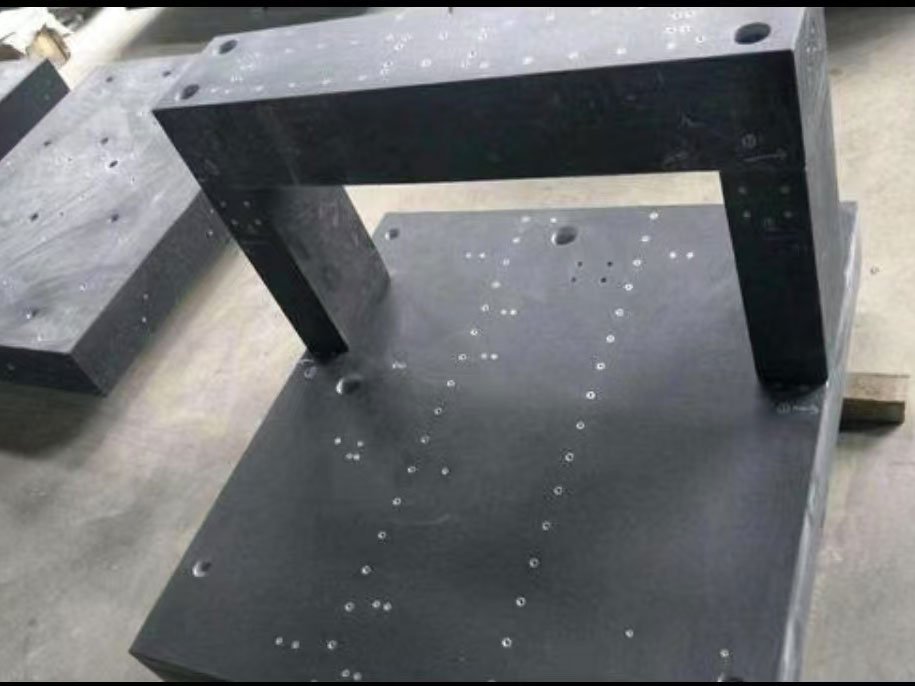

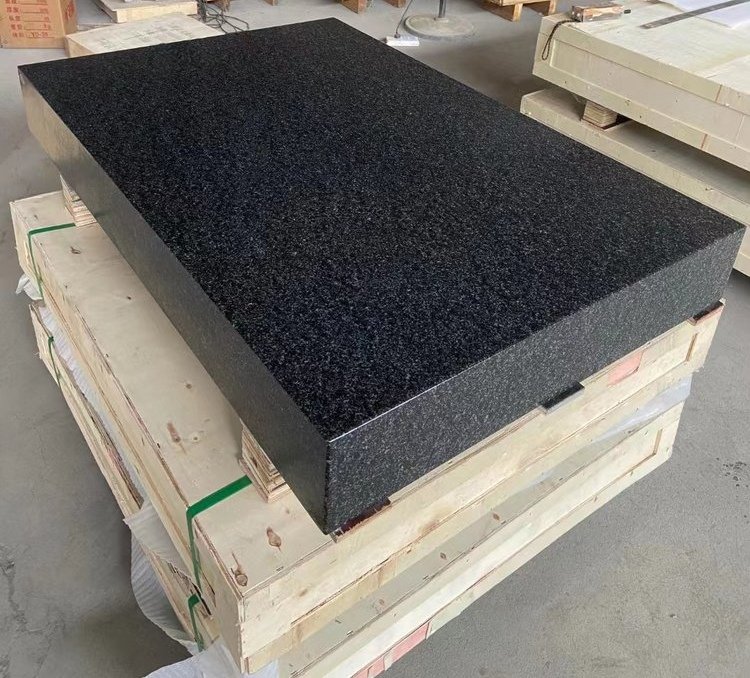

I. Core Advantages (Why Granite + Guide Rails) – Ultra-high Precision: Granite has excellent thermal stability and minimal deformation, maintaining long-term flatness/straightness (up to 0.001mm level) Please provide the text you would like translated.Rigidity and damping: Heavier than cast iron, with greater damping, it offers better vibration resistance, disturbance resistance, and more stable movement. Please provide the text you would like translated.Wear-resistant and rust-free: High hardness, rust-free, and maintenance-free, suitable for precision/clean environments. Please provide the text you would like translated.- Compatible with mainstream rails: air bearings, linear motors, ball/roller rails can all be combined. – II. Mainstream combination methods (commonly used in precision equipment) 1. Granite + air bearing rail (the top choice for ultra-precision) – Structure: Granite base with grooves or attached air bearing rails, the slide is suspended by an air film (no contact) Please provide the text you would like translated.Advantages: Zero friction, zero wear, extremely high straightness/flatness, smooth movement Please provide the text you would like translated.Applications: Three-coordinate measuring machines, lithography machines, optical inspection, semiconductor equipment Please provide the text you would like translated.- Installation: Precision grinding of the base → Ensuring the height and parallelism of the guide rail surface → Matching grinding of the air bearing blocks → Sealing of the air passage → Adjustment of pressure and clearance2. Linear motor + Granite base (high speed and high precision) – Structure: The stator guide rail is installed on the granite base, and the mover is installed on the slide table; no mechanical transmission, direct drive Please provide the text you would like translated.Advantages: High speed, high acceleration, precise positioning, and quick response. Please provide the text you would like translated.- Installation: Ensure the flatness/parallelism of the base → High-precision bonding/screw fixation of the stator guide rails → Calibration of the air gap of the mover → Installation of the encoder feedback 3. Ball/Roller linear guide rails + Granite (General Precision) – Structure: Milling/grinding of the installation reference on the granite base → Fixation of the guide rails with bolts + locating pins Please provide the text you would like translated.Advantages: moderate cost, good rigidity, strong load capacity, and simple maintenance. Please provide the text you would like translated.Applications: Precision machine tools, measuring instruments, automated equipment Please provide the text you would like translated.Installation: Bench surface grinding → Guide rail height/parallelism → Preload control → Slider preloading → Running-in adjustmentIII. Key Installation Processes (Precision Assurance)1. Base Pre-treatment Please provide the text you would like translated.Granite base fine grinding: flatness ≤ 0.002mm/m, roughness Ra ≤ 0.4 Please provide the text you would like translated.Cleaning, degreasing, stress relief, and constant-temperature static placement (for more than 24 hours) Please provide the text you would like translated.2. Guide rail positioning and fixation Please provide the text you would like translated.Reference: Use a marble right-angle square and a laser interferometer to find the level, parallelism and perpendicularity. Please provide the text you would like translated.- Fixed: Please provide the text you would like translated.- Air floatation / linear motor: Epoxy resin bonding + auxiliary bolts (for stress prevention and precision maintenance) Please provide the text you would like translated.Ball guide rail: locating pin + high-strength bolt (uniform torque, anti-loosening) Please provide the text you would like translated.Direct welding is strictly prohibited (granite is not heat-resistant and prone to cracking). Please provide the text you would like translated.3. Precision Calibration Please provide the text you would like translated.Straightness/Flatness: Measured by laser interferometer Please provide the text you would like translated.Parallelism/Perpendicularity: Marble square, dial indicator Please provide the text you would like translated.- Air flotation: Adjust the air pressure and gap to ensure a uniform and stable air film. – Common problems and countermeasures: – Base deformation: Select high-quality Jinan green or Tai Shan green granite; perform aging treatment after processing; apply uniform force during installation and avoid single-point compression. Please provide the text you would like translated.- Loose guide rails / decreased accuracy: Use low-shrinkage epoxy adhesive; add anti-loosening devices to bolts; regularly recheck the preload force. Please provide the text you would like translated.- Unstable air floatation: Clean and dry the air path; Match and grind the air float bloc