High-precision granite platforms, leveraging the unique physical properties of natural stone, have become a critical foundation in industries with extreme accuracy demands. They serve not only as the ultimate “measurement datum” but also as core components in various types of “precision motion systems.”🎯 Primary Application FieldsGranite platforms are primarily deployed in fields that demand exceptional stability and precision:· Precision Measurement & Inspection · Typical Uses: Base platforms for high-accuracy inspection equipment like Coordinate Measuring Machines (CMM) and optical vision measuring systems. · Application Scenarios: Dimensional inspection of mechanical parts, mold acceptance, and precision measurement of electronics (e.g., PCBs, semiconductors). · Key Advantage: The extreme flatness and stability of the platform itself form the reliable foundation for accurate measurement data.· High-End Manufacturing & Machining · Typical Uses: Base or motion platforms for precision CNC machine tools, laser processing equipment (cutting/welding), micro-assembly systems, and dispensing machines. · Application Scenarios: Semiconductor wafer processing and inspection, optical component manufacturing, precision part machining, inspection of mobile phone/glass panels. · Key Advantage: High rigidity dampens vibrations, while a low coefficient of thermal expansion resists dimensional changes from temperature fluctuations, ensuring process stability and product quality.· Scientific Research & Specialized Fields · Typical Uses: Aerospace component testing, micro-gravity simulation, biomedical instrument R&D, precision optical experimental tables. · Key Advantage: Non-magnetic, corrosion-resistant, and highly stable, meeting extreme requirements in specialized environments.✨ Core Advantages & PerformanceThe suitability of granite for these critical roles stems from its inherent physical properties:· Superior Stability: Natural stone has undergone millennia of natural aging, resulting in minimal internal stress and virtually no long-term deformation.· Excellent Accuracy Retention: High hardness (Mohs 6-7, approximately 2-3 times that of cast iron) makes it extremely wear-resistant, maintaining micron-level (μm) accuracy over long periods.· Low Environmental Sensitivity: Very low linear expansion coefficient (approx. 4.6×10⁻⁶/°C), making it highly resistant to temperature changes; also non-corrosive, non-magnetic, and resistant to most acids and alkalis.🚀 Technology Evolution: From Static Base to Dynamic CoreBeyond static measurement platforms, granite is now deeply integrated into advanced motion systems, mainly in two forms:· Granite Linear Modules/Motion Stages: Utilize a granite base for high rigidity, integrated with linear motors and guides. Enable high-speed (>0.2m/s), high-acceleration (up to 5 m/s²), long-travel precision linear motion, with repeatability reaching ±1 micron.· Granite Air Bearing Platforms: Employ air bearings on a granite surface to achieve contactless and frictionless motion. Offer repeatability down to 0.2 microns and are completely oil-free, designed for ultra-clean environments like semiconductor inspection and optical metrology.📝 Selection and Usage GuidelinesKey considerations for choosing and using a granite platform:Key Selection Parameters· Accuracy Grade: National standards (e.g., Chinese GB) classify as 000, 00, 0, 1. Grade 000 is the highest, suitable for top-tier metrology labs.· Dimensions: Table size (e.g., 1000×750mm) and thickness must be chosen based on workpiece size and load.· Load Capacity: Must support the weight of workpieces to ensure sufficient rigidity.· Special Features: Requirement for custom machining like T-slots, threaded holes, or through-holes.Usage and Maintenance Notes· Environment: Ideal conditions are a temperature- and humidity-controlled, vibration-free, clean room.· Installation: Must be leveled using matching supports and placed on a solid foundation.· Operation: Handle workpieces gently; avoid impact or striking. Granite is hard but brittle, and edges can chip.· Maintenance: Clean regularly with alcohol or water; no rust-proof oil is needed. Avoid prolonged exposure to humidity or strong acids/alkalis.This is a translation of the original Chinese article. If you have specific terms or sections that need further clarification or adaptation for a particular audience, please let me know.

Based on your request, here is the English version of the article on the applications of high-precision granite platforms.

Aplicaciones de las plataformas de granito de alta precisión

High-precision granite platforms, leveraging the unique physical properties of natural stone, have become a critical foundation in industries with extreme accuracy demands. They serve not only as the ultimate “measurement datum” but also as core components in various types of “precision motion systems.”

🎯 Primary Application Fields

Granite platforms are primarily deployed in fields that demand exceptional stability and precision:

· Precision Measurement & Inspection

· Typical Uses: Base platforms for high-accuracy inspection equipment like Coordinate Measuring Machines (CMM) and optical vision measuring systems.

· Application Scenarios: Dimensional inspection of mechanical parts, mold acceptance, and precision measurement of electronics (e.g., PCBs, semiconductors).

· Key Advantage: The extreme flatness and stability of the platform itself form the reliable foundation for accurate measurement data.

· High-End Manufacturing & Machining

· Typical Uses: Base or motion platforms for precision CNC machine tools, laser processing equipment (cutting/welding), micro-assembly systems, and dispensing machines.

· Application Scenarios: Semiconductor wafer processing and inspection, optical component manufacturing, precision part machining, inspection of mobile phone/glass panels.

· Key Advantage: High rigidity dampens vibrations, while a low coefficient of thermal expansion resists dimensional changes from temperature fluctuations, ensuring process stability and product quality.

· Scientific Research & Specialized Fields

· Typical Uses: Aerospace component testing, micro-gravity simulation, biomedical instrument R&D, precision optical experimental tables.

· Key Advantage: Non-magnetic, corrosion-resistant, and highly stable, meeting extreme requirements in specialized environments.

✨ Core Advantages & Performance

The suitability of granite for these critical roles stems from its inherent physical properties:

· Superior Stability: Natural stone has undergone millennia of natural aging, resulting in minimal internal stress and virtually no long-term deformation.

· Excellent Accuracy Retention: High hardness (Mohs 6-7, approximately 2-3 times that of cast iron) makes it extremely wear-resistant, maintaining micron-level (μm) accuracy over long periods.

· Low Environmental Sensitivity: Very low linear expansion coefficient (approx. 4.6×10⁻⁶/°C), making it highly resistant to temperature changes; also non-corrosive, non-magnetic, and resistant to most acids and alkalis.

🚀 Technology Evolution: From Static Base to Dynamic Core

Beyond static measurement platforms, granite is now deeply integrated into advanced motion systems, mainly in two forms:

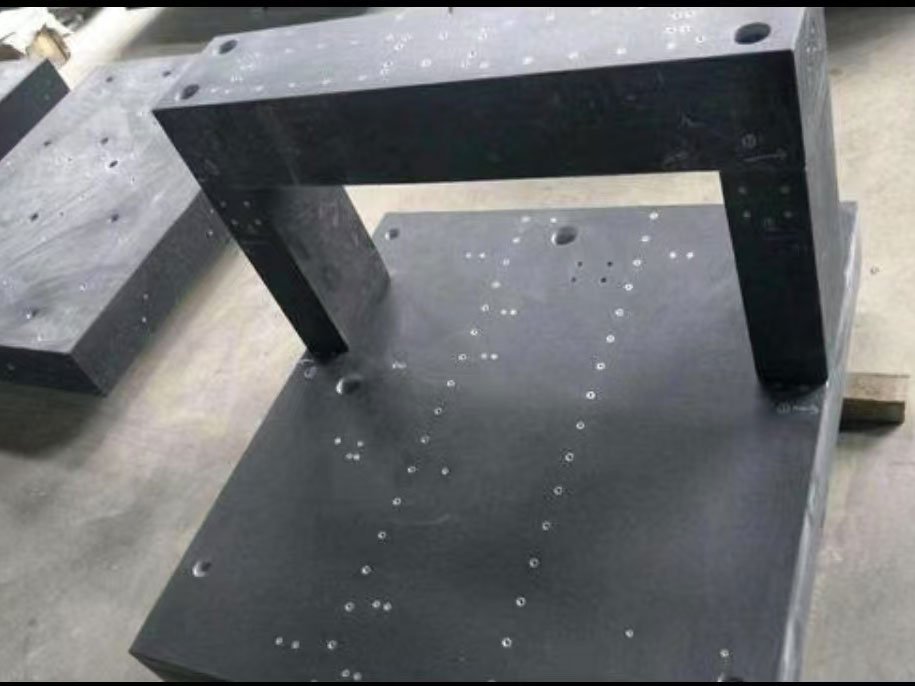

· Granite Linear Modules/Motion Stages: Utilize a granite base for high rigidity, integrated with linear motors and guides. Enable high-speed (>0.2m/s), high-acceleration (up to 5 m/s²), long-travel precision linear motion, with repeatability reaching ±1 micron.

· Granite Air Bearing Platforms: Employ air bearings on a granite surface to achieve contactless and frictionless motion. Offer repeatability down to 0.2 microns and are completely oil-free, designed for ultra-clean environments like semiconductor inspection and optical metrology.

📝 Selection and Usage Guidelines

Key considerations for choosing and using a granite platform:

Key Selection Parameters

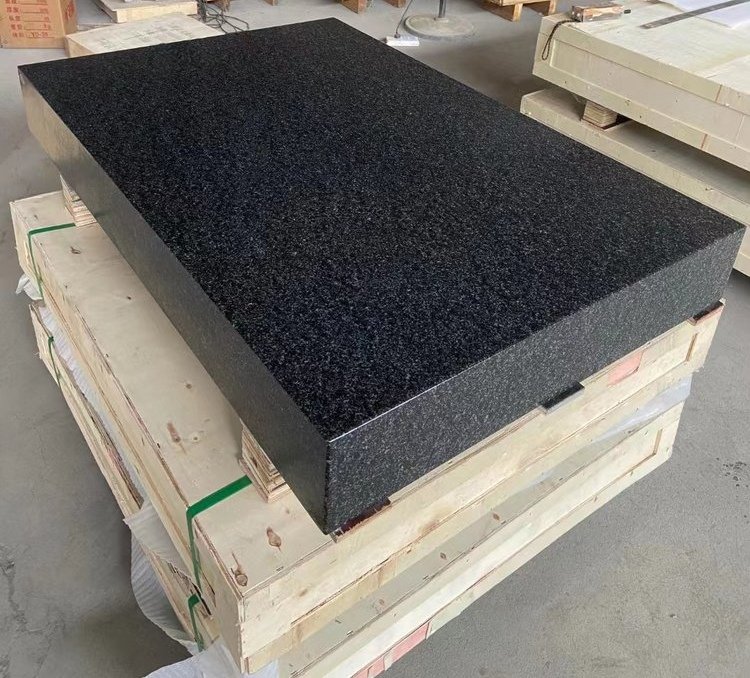

· Accuracy Grade: National standards (e.g., Chinese GB) classify as 000, 00, 0, 1. Grade 000 is the highest, suitable for top-tier metrology labs.

· Dimensions: Table size (e.g., 1000×750mm) and thickness must be chosen based on workpiece size and load.

· Load Capacity: Must support the weight of workpieces to ensure sufficient rigidity.

· Special Features: Requirement for custom machining like T-slots, threaded holes, or through-holes.

Usage and Maintenance Notes

· Environment: Ideal conditions are a temperature- and humidity-controlled, vibration-free, clean room.

· Installation: Must be leveled using matching supports and placed on a solid foundation.

· Operation: Handle workpieces gently; avoid impact or striking. Granite is hard but brittle, and edges can chip.

· Maintenance: Clean regularly with alcohol or water; no rust-proof oil is needed. Avoid prolonged exposure to humidity or strong acids/alkalis.