There are many methods for measuring flatness, here are several common ones:Gap gauge measurement method: The gap gauge is mainly used for the measurement of clearance spacing, and can only be used for rough measurement of flatness.

Before use, the and dust on the gap gauge and the workpiece must be removed.

When using, one or more pieces can be overlapped and inserted into the gap, and it is appropriate feel a slight drag.

When measuring, the action should be gentle, and it is not allowed to forcefully insert.

Liquid plane method: The liquid plane method uses liquid plane as the measuring reference surface, which is composed of the liquid surface in the communicating tank, and then the sensor is used for measurement.

It is suitable for measuring theness of large continuous or discontinuous planes, but the measurement time is long and it is sensitive to temperature.

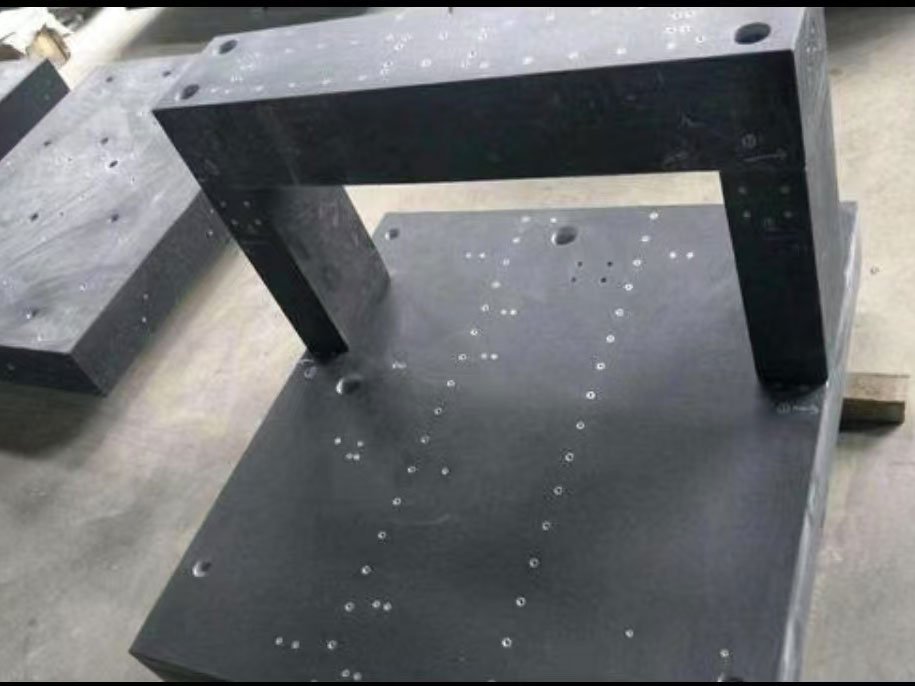

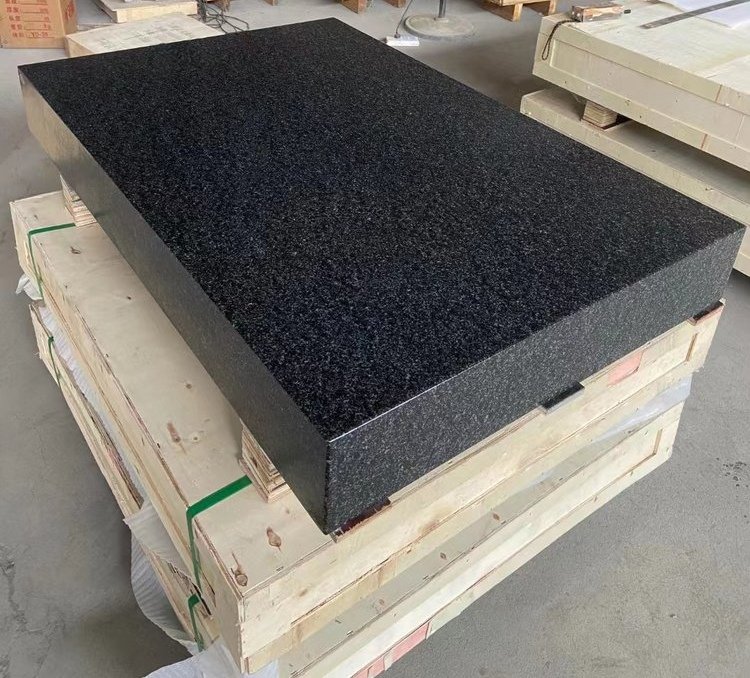

Dial gauge measurement method: The dial gauge measurement method places workpiece to be measured and the micrometer on the standard flat plate, with the standard flat plate as the measuring reference surface, and the micrometer is used to measure along the surface point by point or along several straight lines.

It is divided into the three-point method and the diagonal method: the three-point method uses the ideal plane determined by three points with the farthest distance on the actual surface to be measured as the evaluation reference surface; the diagonal method first adjusts the four corner points on the actual surface to be by two during actual measurement.

Flat crystal interferometry: The working surface of the optical flat crystal is used to reflect the ideal plane, and the degree of curvature of the fringes directly determines the flatness error value of the measured surface.

It is mainly used to measure small planes with smooth surfaces, such as the measuring surface of the dividing, the working surface of the gauge, and the optical lens.

Beam plane method: Measuring with a collimator and a target mirror, the beam plane formed by three points farthest apart on the actual surface is used as the reference plane for measuring the flatness error.

Laser flatness measuring instrument: Used to measure the flatness of large planes.

These methods have their own advantages and disadvantages, and the selection of the appropriate method depends on the size, shape, surface finish of the object to be, and the required measurement accuracy.