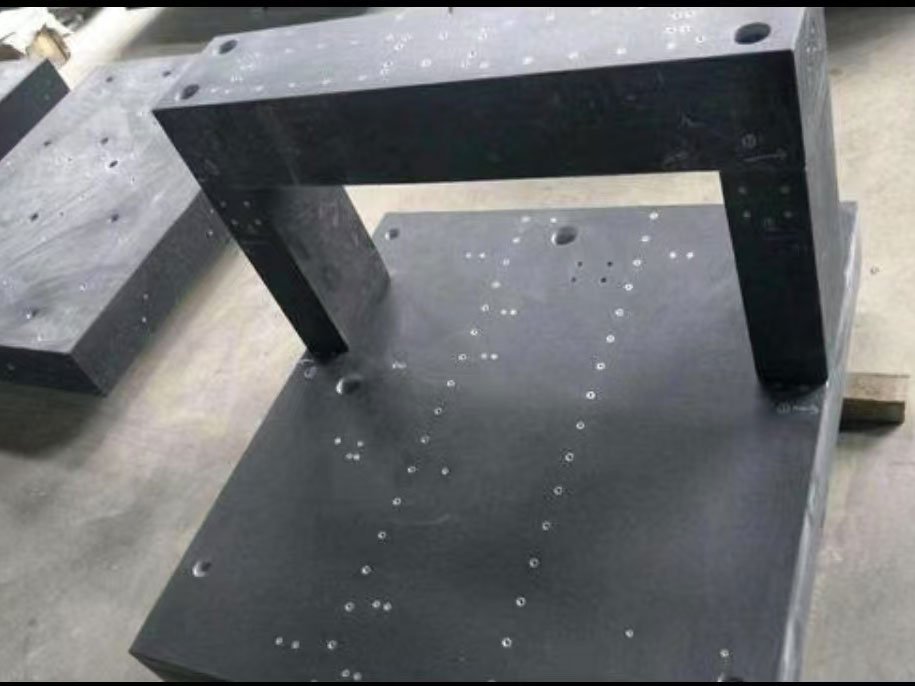

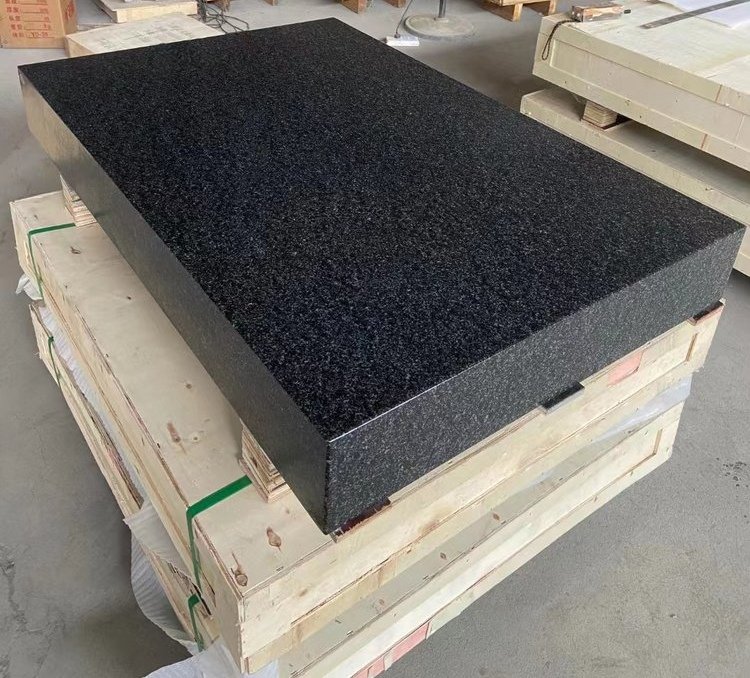

Applications of Granite Precision Platforms in Industrial Metrology and Manufacturing Granite precision platforms, also known as granite surface plates or marble measuring tables, are the unrivaled gold standard in high-precision industrial measurement and manufacturing. Forged by millions of years of natural geological processes and refined through high-precision CNC machining and hand lapping, these platforms deliver exceptional dimensional stability, wear resistance and environmental adaptability that far surpass traditional metal alternatives like cast iron and steel. As a core foundational tool, they are widely integrated into various high-precision industrial scenarios, underpinning the accuracy and reliability of production and quality control across key manufacturing sectors. The unique natural properties of high-grade granite are the cornerstone of its superior performance in industrial applications. Composed primarily of pyroxene (35-45%), plagioclase feldspar (25-35%) and trace minerals such as olivine and biotite, granite platforms have a dense crystalline structure with internal stress fully released through natural aging, eliminating post-processing deformation even under long-term heavy loads (up to 500 kg/m² for standard models). With a Mohs hardness of 6-7, they exhibit remarkable wear resistance, maintaining surface precision after over 10,000 measurement cycles. Their linear expansion coefficient is only 5.5 × 10⁻⁶/℃, one-third that of cast iron, ensuring minimal dimensional change under temperature fluctuations. Additionally, granite is inherently corrosion-resistant to acids, alkalis and industrial solvents, non-magnetic to avoid interfering with precision magnetic measuring tools, and boasts excellent damping properties that absorb vibrations far better than metal materials—critical for sensitive high-precision operations. In the field of precision metrology, granite platforms are the indispensable core component of coordinate measuring machines (CMMs), serving as the foundational workbench for 3D dimensional inspection of mechanical components. Equipped with standardized reference markers on their working surfaces, they enable rapid calibration and positioning of CMM probes, streamlining measurement workflows for aerospace parts, automotive precision components and other high-precision parts with strict form and dimensional deviation requirements. Accredited calibration labs also rely on custom granite measuring tools such as granite master squares—precision-ground and hand-lapped to tolerances as tight as 0.001 mm over 300 mm—to verify perpendicularity, flatness and parallelism of metrological equipment, upholding the traceability of measurement standards in line with ISO/IEC 17025 requirements. The machine tool industry is another major application area for granite precision platforms, where they play a multi-faceted role in ensuring machining accuracy. As machine tool worktables, they provide a rigid, ultra-flat surface for high-speed milling, grinding and precision cutting, maintaining consistent flatness without deformation from prolonged use or temperature changes. For tool calibration and alignment, granite plates with Grade 0 or 00 surface tolerances act as a reliable reference for verifying the accuracy of cutting heads, jigs and fixtures, laying the groundwork for precise tool setup. They also serve as dedicated inspection and measurement stations for post-machining component checks, including dimensional verification, squareness and flatness measurements, with their wear resistance preserving long-term accuracy for daily use. For high-sensitivity operations like fine boring and ultra-precision grinding, granite’s superior vibration damping properties make it the ideal material for vibration-free operation platforms, while advanced machine designs even integrate granite components directly into machine bases to enhance overall stability, reduce thermal deformation and extend the lifetime accuracy of equipment. Beyond metrology and machine tools, granite precision platforms find extensive use in other high-tech and manufacturing sectors. In semiconductor and optoelectronic manufacturing, they are used for the bases of lithography machine worktables and wafer cutting machines, delivering the high rigidity and temperature stability required for nanometer-scale semiconductor processing. The electronics and instrumentation industry leverages granite modular platforms for efficient dimensional measurement, replacing multiple surface measurement tools and significantly cutting down inspection time for precision electronic components. In the plastics industry, these platforms support strict quality control and precision measurement of plastic products, ensuring compliance with dimensional specifications. Even in heavy manufacturing fields such as wind power and nuclear energy, large custom granite platforms are integrated into high-precision measuring systems for oversized