Aunque las herramientas de medición de granito presentan importantes ventajas, como su alta precisión y su resistencia a la corrosión, en las aplicaciones prácticas siguen existiendo las siguientes desventajas, que deben sopesarse y seleccionarse en función de escenarios específicos:

- Crispy texture with poor impact resistance

Performance: Although granite has high hardness, it is brittle and prone to cracking or angular collapse when subjected to external impacts such as falling or heavy objects, even leading to overall fracture.

Impact: Improper operation during transportation, installation, or use may cause irreversible damage and increase maintenance costs.

Case: When a certain automobile manufacturer was using a granite inspection platform, the edge was damaged due to transportation collision, and needed to be returned to the factory for repair, which delayed the production schedule. - Difficult processing and high cost

Performance: Granite requires high-precision grinding, polishing and other processes to meet measurement requirements, with a long processing cycle and high equipment and technical requirements.

Impact: The cost of customized measuring tools is significantly higher than that of metal materials, for example, the price of imported granite angle rulers is 10% -15% higher than the industry average.

Data: Grinding workers for high-end granite measuring tools require over 20 years of experience, with labor costs accounting for over 30%. - Heavy weight, inconvenient to transport and install

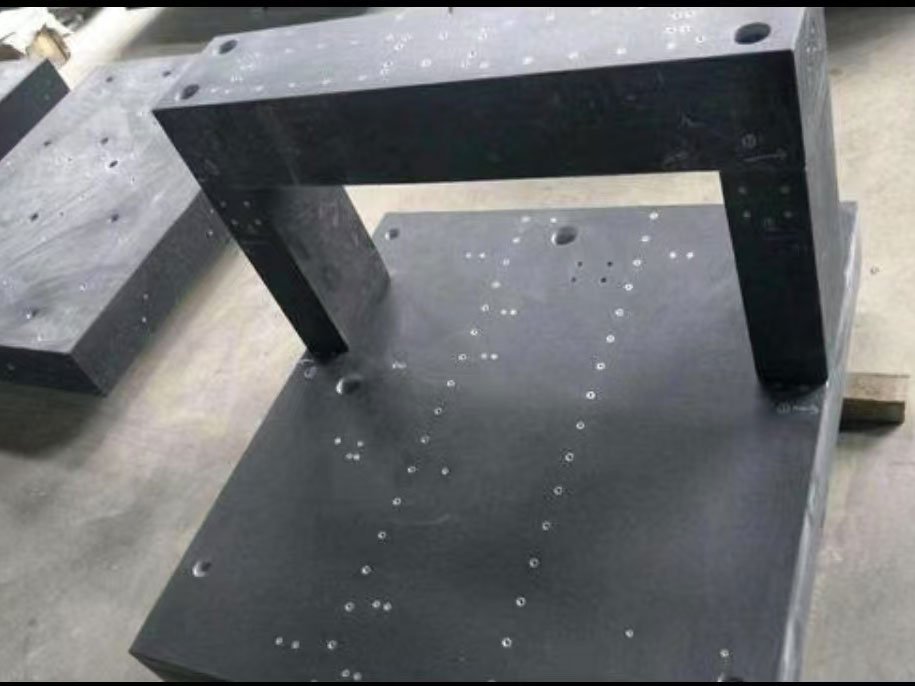

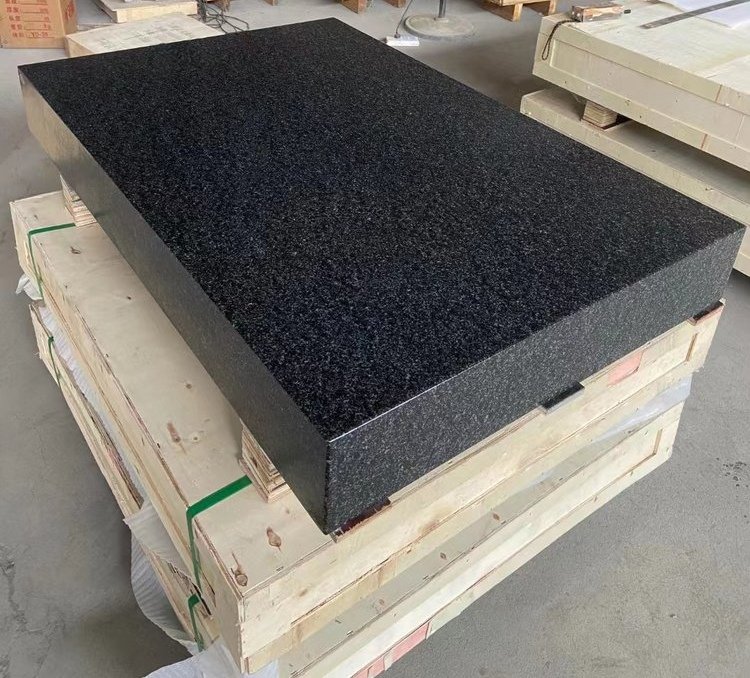

Performance: Granite has a high density (about 2.7-3.1g/cm ³), and large measuring tools (such as platforms and square rulers) can weigh several tons, requiring specialized equipment for handling.

Impact: Increased logistics costs and strict requirements for installation site load-bearing capacity and space limit its application in mobile scenarios.

Case: A semiconductor company customized a 5m × 2m granite platform, requiring the use of a crane and reinforcement of the factory floor, with an additional expenditure of over 50000 yuan. - Poor fire resistance

Performance: Granite contains quartz components and is prone to undergo crystal transformation at high temperatures, leading to volume expansion and even cracking.

Impact: In high-temperature environments (such as metallurgy and casting workshops) or fire scenarios, measuring tools may be damaged, affecting measurement accuracy.

Data: The refractory temperature of granite is usually below 800 ℃, while cast iron measuring tools can withstand high temperatures above 1200 ℃. - Natural defects affect quality

Performance: Natural granite may have defects such as color difference, color lines, and interlayer (stone reinforcement), and qualified materials need to be screened through pre layout and testing.

Impact: Defects may lead to uneven surface or reduced strength of measuring tools, such as cracks in stone bars, which may decrease structural stability.

Case: A granite square ruler purchased by a precision manufacturing enterprise was returned due to color difference issues, and the re selection of materials resulted in a 2-week delay in delivery time. - Customization flexibility is limited

Performance: Due to processing technology limitations, the customized size and shape complexity of granite measuring tools are lower than those of metal materials, and the delivery time is longer.

Impact: It is difficult to meet the demand for ultra large (such as>8m) or irregular measuring tools, for example, special angle measuring tools for semiconductor equipment may not be produced.

Data: Only 30% of manufacturers support customized granite measuring tools over 8m in length, with a delivery time of over 45 days. - Easy brittleness in low temperature environments

Performance: At extreme low temperatures (such as<-20 ℃), the brittleness of granite increases and its impact resistance further decreases.

Impact: When used in cold regions or cold storage scenarios, additional protective measures are required, which limits its application scope.