Keywords: Granite machining, diamond grinding, vibration aging, automated fabrication

The production of granite components involves sophisticated multi-stage processes:

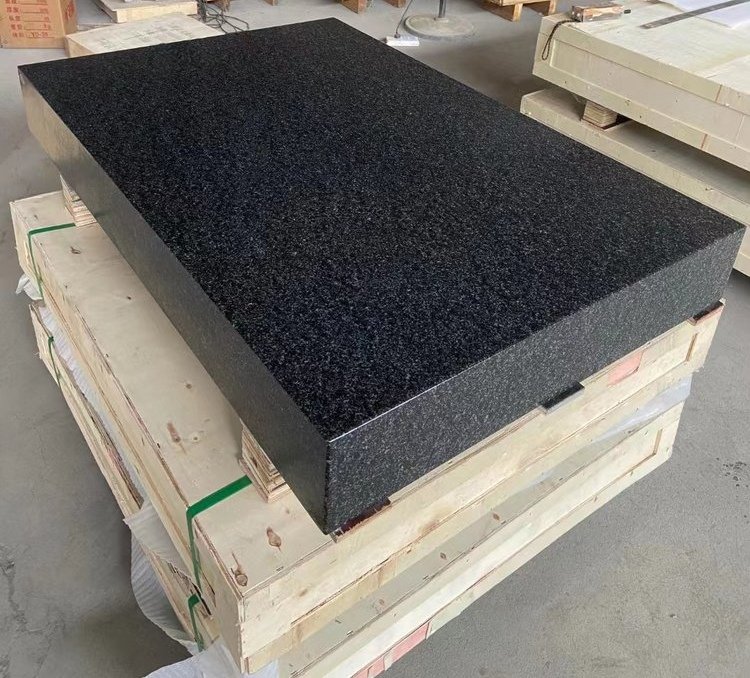

- Block Selection: High-purity granite blocks (SiO₂ >70%) are sourced using ultrasonic testing to detect internal flaws.

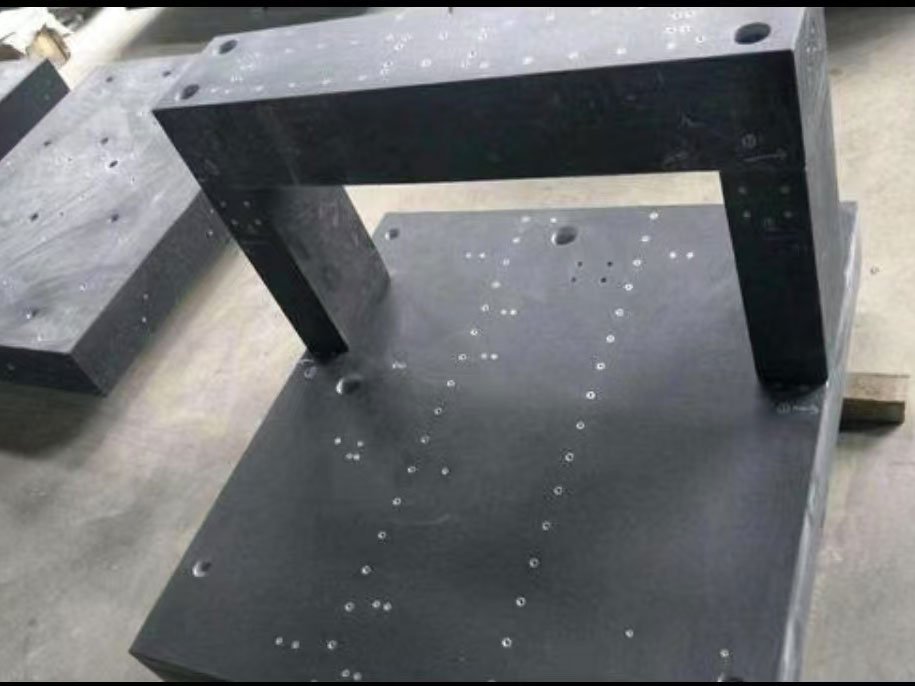

- Precision Shaping: Computer-controlled diamond wire saws cut blanks to ±0.5mm tolerance.

- Grinding & Lapping: Automated systems employ diamond wheels and nanometer-grade slurries to achieve surface finishes below Ra 0.2μm.

- Vibration Aging: Post-processing resonant frequency vibration eliminates residual stresses, improving long-term stability by 40%.

- Quality Control: Laser interferometers and CMMs verify flatness across 21 points, ensuring compliance with ISO 8512-2.

Facilities like Botou Jingda utilize robotic handling and AI-driven inspection, reducing human error to <0.1%. Automated lines now achieve 99% first-pass yield for Grade 00 components.