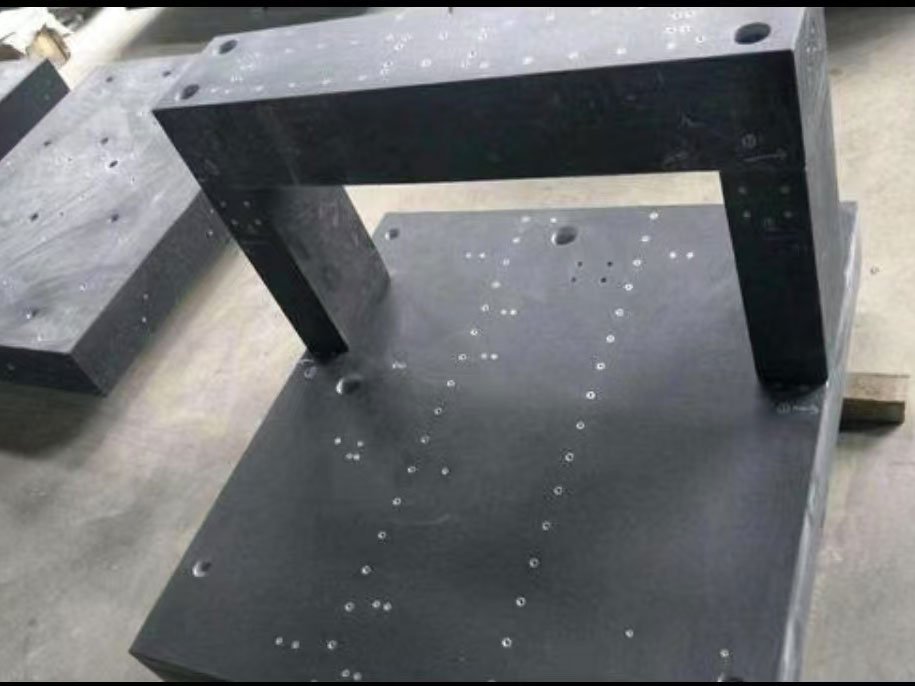

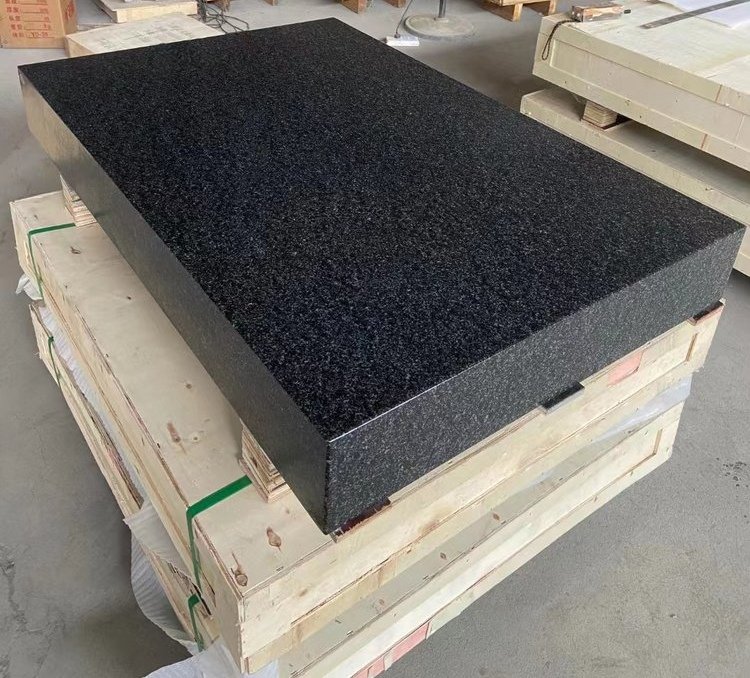

The marble platform is a precision measuring tool made of marble, also known as a granite plate. It is crafted from high-quality “Jinan Green” stone through mechanical processing and hand-polishing. The main mineral components of the marble platform are pyroxene, plagioclase, a small amount of olivine, biotite, and trace amounts of magnetite. It has a black luster, a precise structure, and after billions of years of aging, it has a uniform texture, good stability, high strength, and high hardness, maintaining high precision under heavy loads. It is used in industrial production and laboratory measurement work.The marble plate is also called a granite plate, rock plate, marble platform, granite platform, or rock platform. It is a precision reference measurement tool made of natural stone, used for the flatness inspection of the working surfaces of instruments, precision tools, and mechanical parts, especially for high-precision measurements.The marble platform is made from high-quality “Jinan Green”, “Tai Shan Green”, “Tai Shan Green White Grain” and other stones through mechanical processing and hand-polishing. Its surface has an extremely high degree of smoothness, allowing for smooth movement during measurement without any sticking sensation. These stones all have a black luster, a precise structure, a uniform texture, good stability, high strength, and high hardness. They also have the advantages of being resistant to acid and alkali, wear-resistant, non-magnetic, and non-deformable, enabling them to be used in a wider range of working conditions.Product FeaturesThe main features of the marble platform are stable precision and convenient maintenance. This is because:① The marble platform has a dense structure, a smooth and wear-resistant surface, and a small roughness value;② The marble has undergone long-term natural aging, and all internal stresses have completely disappeared, making the material stable and not prone to deformation;③ It is resistant to acid, alkali, corrosion, and magnetic fields;④ It does not absorb moisture and rust, making it easy to use and maintain;⑤ It has a small coefficient of thermal expansion and is less affected by temperature;⑥ When the working surface is hit or scratched, it will only produce indentations, not protrusions or burrs, which do not affect the measurement accuracy.The main disadvantage of the rock plate is that it cannot withstand excessive impact or knocking, and it may deform in high humidity conditions, with a moisture absorption rate of 1%.ApplicationsIt is suitable for various inspection tasks and serves as a reference plane for precision measurements. It is mainly used as a reference surface for the inspection and measurement of mechanical parts, checking the dimensional accuracy or behavioral deviations of parts, and can also be used for precise marking. It is an indispensable plane reference measuring tool in mechanical manufacturing inspections. According to the types of marble platforms, there are different technical requirements for gray cast iron castings, malleable cast iron castings, and ductile iron castings. Inspections can be carried out according to the conditions of each factory and the inspection and acceptance procedures.