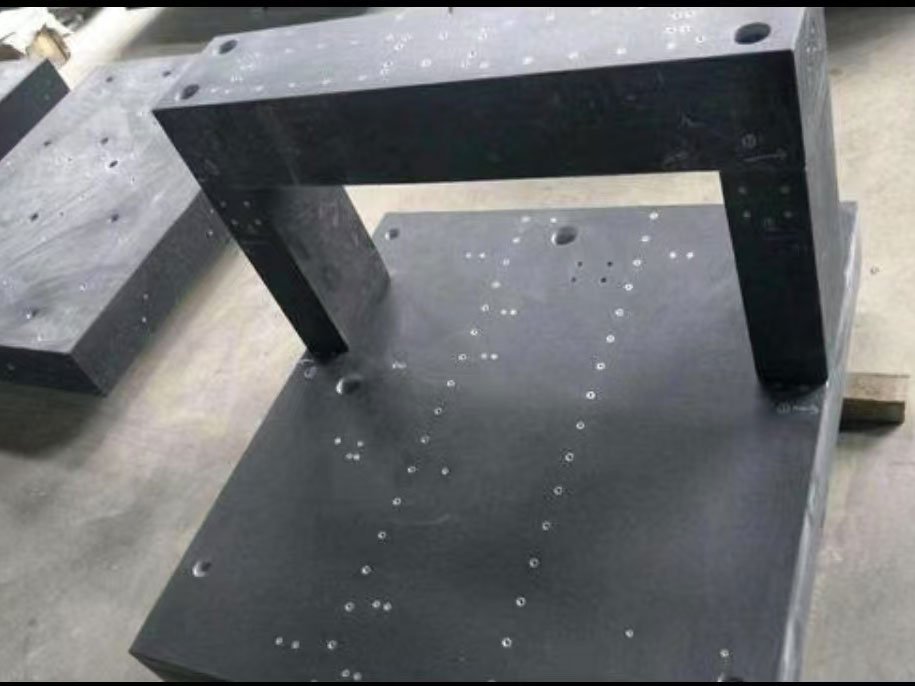

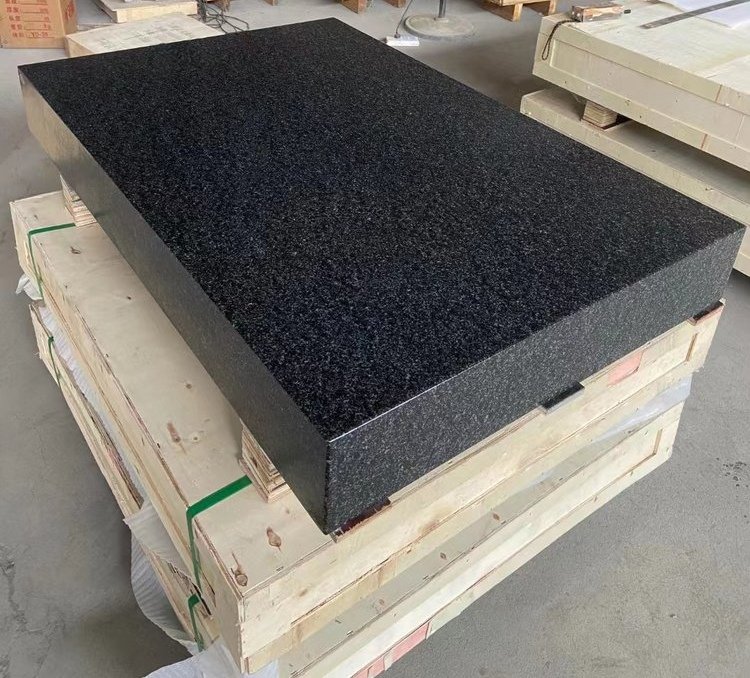

In the realm of precision manufacturing, accuracy is an eternal pursuit. As the cornerstone of high-end equipment such as coordinate measuring (CMMs), optical platforms, and semiconductor lithography devices, the flatness of high-precision granite platforms directly determines the precision limits of the entire measurement or production system You might assume that such high-tech products are inevitably crafted by fully automatic CNC machines. However, an astonishing fact is that: the final lapping process to achieve micron even sub-micron level precision still has to be completed manually by experienced craftsmen.

This is not a case of outdated technology, but a perfect combination of science, experience and art. Here are the four core reasons why manual lapping is irreplaceable:

- Dynamic Correction, Achieving Ultimate Global Flatness machining precision of CNC machines is limited by the precision of their own guides and screws, as well as the effects of thermal deformation, which is a “static” replication process Manual lapping, on the other hand, is a “dynamic measurement-feedback-correction” closed-loop process.

Craftsmen use ultra-precision instruments such electronic levels, autocollimators, and laser interferometers to repeatedly measure the workpiece. Like sculptors, they “perceive” which areas of the workpiece surface “peaks” and which are “valleys” based on data, and then selectively lap certain parts. Through thousands of such cycles, the overall surface undulations are gradually conver within a few microns, achieving nearly perfect global flatness. This is an intelligent correction process that is difficult for any programmed machine to achieve.

- “Slow Produces Finer Work”, Precise Control of Internal Stress

Granite is a natural material with internal stress. Mechanical processing, especially heavy cutting, will introduce stress and cause the original stress to re-balance, resulting in slight deformation during subsequent use and destroying precision.

Manual lapping is a “gentle” process with pressure and low heat. Craftsmen follow a strict procedure: lap a layer → let it rest for a period of time (from days to weeks) → measure → lap again This long process allows the internal stress to be fully and naturally released, making the material structure thoroughly stable. This kind of patience “to have a dialogue with the material” is something machine processing pursuing short-term efficiency cannot provide.

- Creating a perfect isotropic surface

For a precision measurement platform, it’s not enough for the surface to be merelyflat.” Its microscopic texture is also crucial. Mechanical grinding can easily produce regular scratches in a single direction, leading to inconsistent friction and precision performance in different moving directions.

ienced craftsmen use an endless variety of gestures (such as figure-8 or spiral shapes) for grinding, making the movement trajectory of the abrasive random and without a dominant. The result is an isotropic surface, which means that no matter which direction the instrument or workpiece moves on the platform, a consistent and smooth experience and a high repeatability of accuracy can be achieved.

- Dealing with the innate inhomogeneity of materials

Granite is composed of various minerals such as quartz, feldspar and mica, each with different hardness. Mechanical grinding plates grind indiscriminately, resulting in softer minerals being over-cut, while hard mineral particles protrude causing microscopic unevenness.

Craftsmen, through long-term practice, accumulate a “feeling” that allows them to subtly adjust the grinding pressure and angle, different hardness mineral components more evenly, and thus obtain a surface that is overall uniform, dense, and wear-resistant.

In summary, the grinding process of high-precision is a perfect fusion of modern precision measurement technology and traditional craftsmanship. CNC machine tools are responsible for efficient “rough work,” quickly removing the excess; while human craftsmen responsible for the final “finishing,” elevating cold rocks to precision masterpieces at the micron level, with their irreplaceable perception, judgment, and experience