The Cornerstone of the Precision Era

In the race for micron- and even nanometer-level precision, any subtle thermal deformation, vibration, or stress can become the key success or failure. High-end manufacturing, precision measurement, and cutting-edge scientific research all seek an absolutely stable and reliable reference plane. It is under such extreme demands that granite platforms, with their unique physical characteristics derived from billions of years of geological deposition, have become an irreplaceable choice.

I. Why Granite? Unveiling Excellent Physical Properties

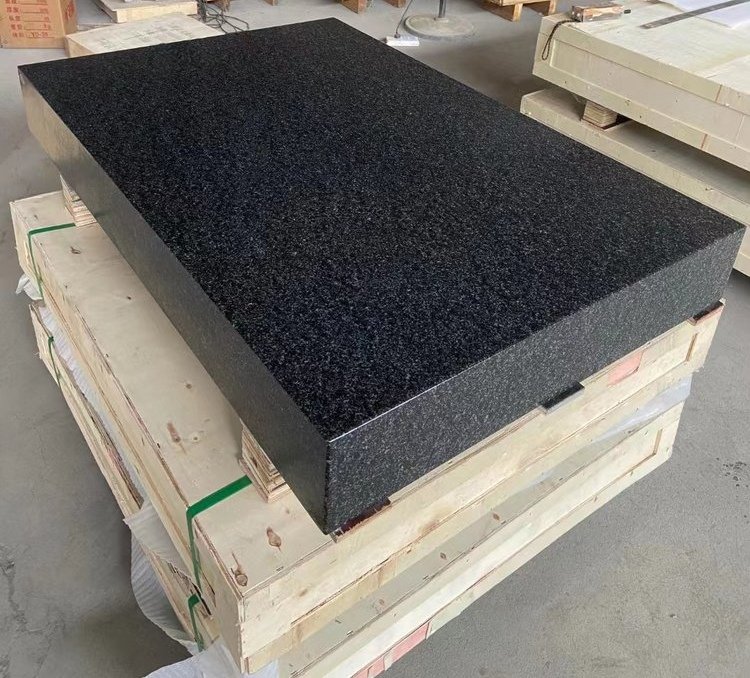

Precision granite platforms are not ordinary stone materials. They typically select high-quality natural granite with the most uniform and stable structure, such as “Jinan” or “Mount Tai Blue,” and undergo months of natural aging treatment to eliminate internal stress. Its core advantages stem from the material itself:

Extremely high dimensional stability After billions of years of natural aging, the internal stress of granite has been completely released, and its coefficient of thermal expansion is extremely low (usually only 0.5~12×10⁻⁶/℃), which is only 1/3 or even lower than cast iron. This means it is extremely insensitive to changes in ambient temperature, provide a long-term, stable reference plane, and eliminate “precision drift.”

Outstanding vibration damping performance: The complex crystal structure inside granite can effectively absorb and dissipate energy, and its damping coefficient is 8-10 times that of cast iron. It can quickly suppress small vibrations from the device itself or the external environment, providing a “” working environment for laser interferometers and ultra-high precision sensors, ensuring the clarity and accuracy of measurement data.

Astonishing hardness and wear resistance: With a highs hardness, it is not easy to scratch or wear. Under normal use, its precision can remain unchanged for decades, and the life cycle cost is far lower than that of metal that require regular scraping and grinding maintenance.

Corrosion resistance and non-magnetism: Withstands acid and alkali, prevents rust, and is never magnetic making it especially suitable for chemical laboratories, MRI environments, and precision measurement occasions that are sensitive to magnetism.

II. Core Application Scenarios: Where Does This Ultimate Precision?

Metrology and Inspection: As the ideal base for coordinate measuring machines (CMMs), laser interferometers, optical imagers, and roundness testers, is the benchmark for national metrology institutes and quality control laboratories.

Semiconductor manufacturing: Used in photolithography machines, wafer inspection equipment, bonders, etc, its stability directly affects the yield of chips.

Precision Machining and Optics: As the workbench or base for ultra-precision machine tools, high-precision grinding, and optical milling machines, as well as the grinding platform for optical lenses.

Scientific Research: In cutting-edge fields such as gravitational wave detection and biotechnology, provides an absolute benchmark for experimental equipment.

III. How to Choose a Qualified Precision Granite Platform? (Selection Guide)

When choosing a precision granite platform it’s crucial not to overlook the following points beyond price and size:

Accuracy Grade: Based on national or ISO standards, common grades include 00, , and 1. Grade 00 represents the highest precision with extremely small flatness tolerance (e.g., ±(1.5 0.5L1000) μm). Always request inspection reports from a third-party authoritative agency.

Stone Quality: Inquire about the origin and variety of the, as high-quality stone forms the basis for performance.

Process and Aging: Understand whether the manufacturer has undergone natural aging and precision grinding processes. Manually scraped typically outperform mechanically ground ones.

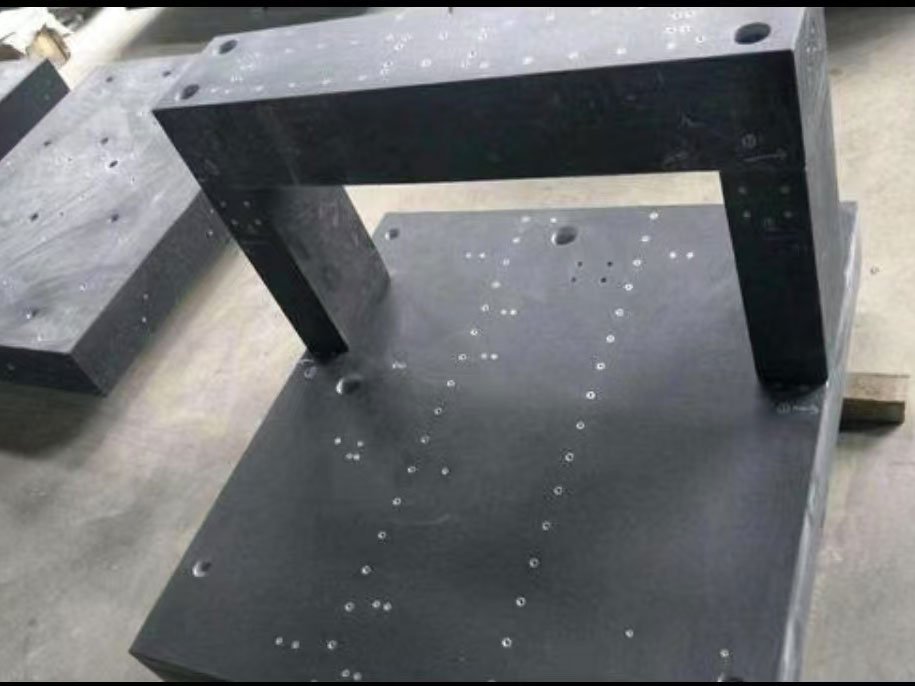

Structural Design: For large platforms, pay attention to the rib structure design and support point layout to ensure minimal deformation under load.

Qualifications and Service: Choose a manufacturer with mature experience, capable of providing customized design (such as drilling, grooving, inlays), and long-term re-ion and maintenance services.

IV. Precision Granite Platform vs. Traditional Cast Iron Platform:

Characteristics Precision Granite Platform Traditional Cast Iron Platform

Stability (No internal stress, low thermal expansion) Good (But there is a risk of internal stress and aging deformation)

Damping Excellent (8-10 times that of cast) Poor

Abrasion resistance Excellent Good (But requires regular maintenance)

Maintenance cost Low (Basically maintenance-free) High (Regular scraping, rust prevention)

Corrosion resistance Excellent Poor (Surface treatment needed)

Initial cost Higher Lower

Invest in the future, choose the cornerstone of eternal precision

A granite platform is far from an ordinary industrial product. It is an infrastructure investment for precision endeavors for decades to come. It embodies the relentless pursuit of ultimate precision, absolute stability, long-term reliability. When choosing, please look beyond the initial price tag and focus on the value it brings throughout the product lifecycle in terms of value enhancement, risk reduction, optimized total cost of ownership.