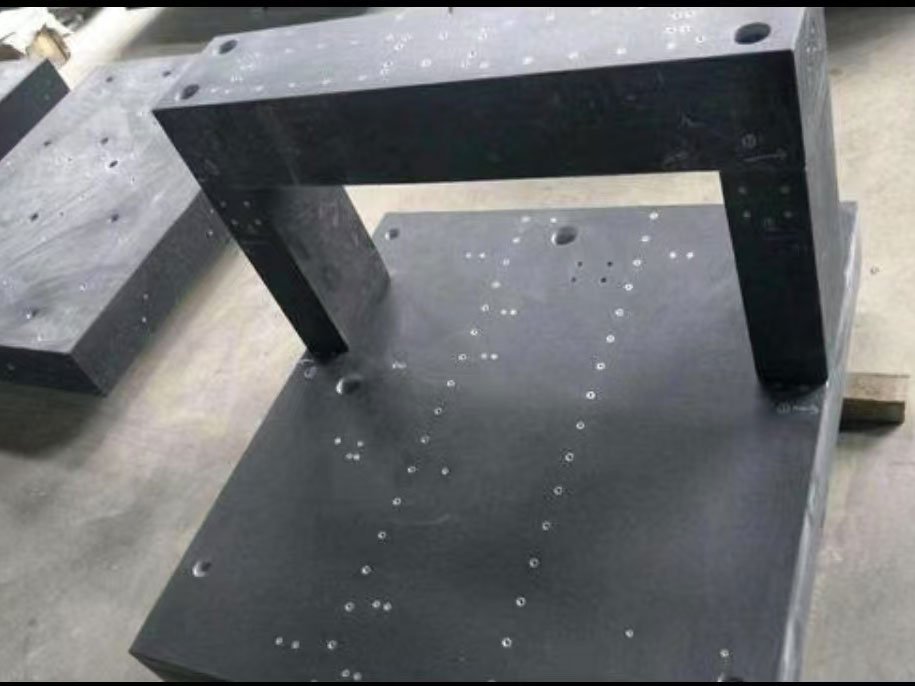

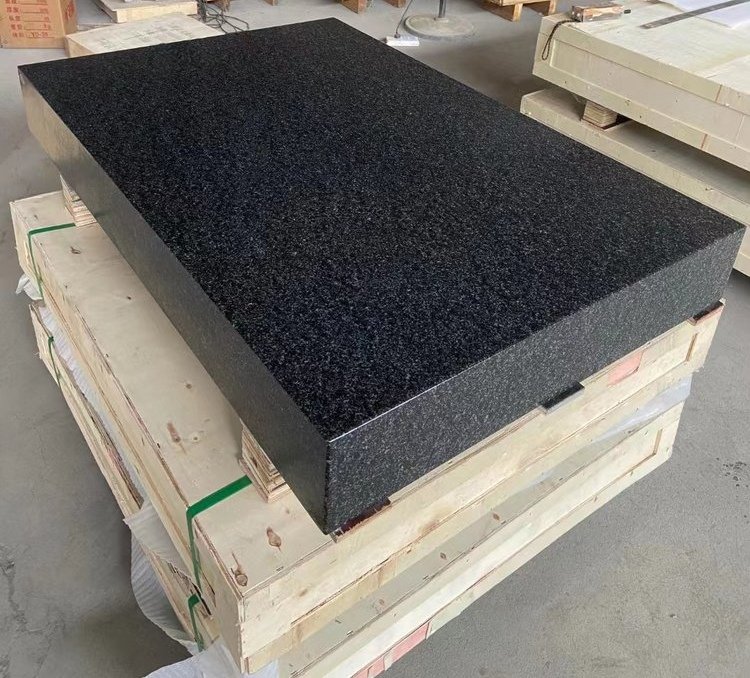

1. Semiconductor and integrated circuit manufacturing · Photolithography machine and workbench: The low thermal deformation characteristics of granite ensure the stability of nanoscale carving. · Wafer inspection and packaging equipment: Used for high-precision platforms to reduce the effects of vibration and temperature fluctuations. 2. Precision measuring and metrology instruments · Coordinate measuring machine (CMM): Granite guide rails and provide long-term dimensional stability, ensuring micrometer-level measurement accuracy. · Laser interferometer, optical profiler: Used as a reference plane to ensure precise alignment of paths. 3. High-end machine tools and machining centers · Ultra-precision machine bed: Used for mirror processing, micro-turning equipment, suppressing and maintaining geometric accuracy. · High-precision grinding machines and milling machines: Granite components enhance equipment rigidity and reduce machining errors caused by thermal deformation. .

- Optical and optoelectronic systems · Telescope support: Large granite structures support lens groups, resisting environmental deformation. · Laser emitter platform: Main beam path stability in laser cutting, medical laser equipment.

5. Scientific research and special fields · Particle accelerator beamline guide: Institutions such as CERN use to support precision magnets. · Gravitational wave detection device (such as LIGO): Adopt a giant granite base to isolate seismic interference.