What should be paid attention to when grinding marble?

The selection of grinding materials generally uses corundum boron carbide, diamond powder, chromium oxide, iron oxide, etc.

The following points should be noted during the grinding process:

. Select a good grinding powder, the workplace should be clean, so as not to scratch the surface of the workpiece.

2. Master the grinding and grinding pressure; for surfaces with high accuracy and complex shapes, the grinding speed should be lower. The size of the grinding pressure is determined by the nature of the workpiece material the grinding material. When the grinding pressure is 0.15~0.2MPa, the grinding efficiency is _.

3. When, generally use a larger pressure and a lower speed for rough grinding, and then use a smaller pressure and a higher speed for fine grinding after the geometric shape is basically qualified.

4. Select the appropriate grinding tool to avoid too fast wear of the grinding tool.

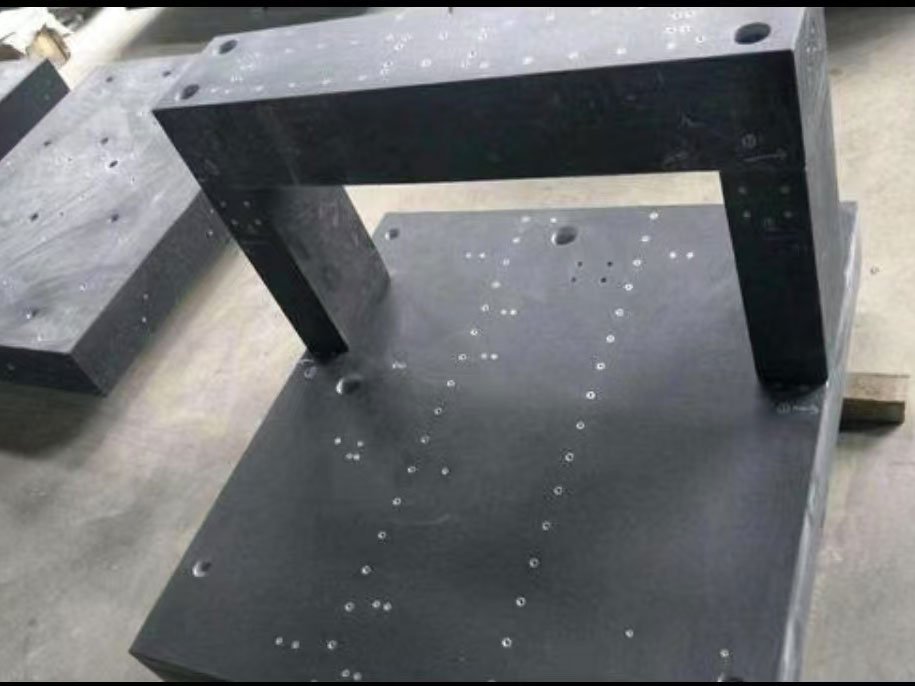

Maintenance steps for marble platforms

Maintenance steps for marble platforms:

- Check the accuracy of the marble platform to determine its current error.

- Use grinding sand and grinding tools to roughly grind the marble platform, and achieve flatness requirements of the benchmark through rough grinding.

- After rough grinding, the marble platform is further semi-fine ground to remove deeper scratches and make the marble achieve the standard flatness.

- Fine grind the marble platform work surface to achieve the desired accuracy.

- Check the accuracy of the marble platform fine grinding, and then check the accuracy of the marble platform after placing it for a while.

Note: The production and maintenance of marble platforms need to be carried out a constant temperature room. High-precision marble platforms also have requirements for indoor humidity, generally requiring a temperature of 20±2° and a humidity of 35%

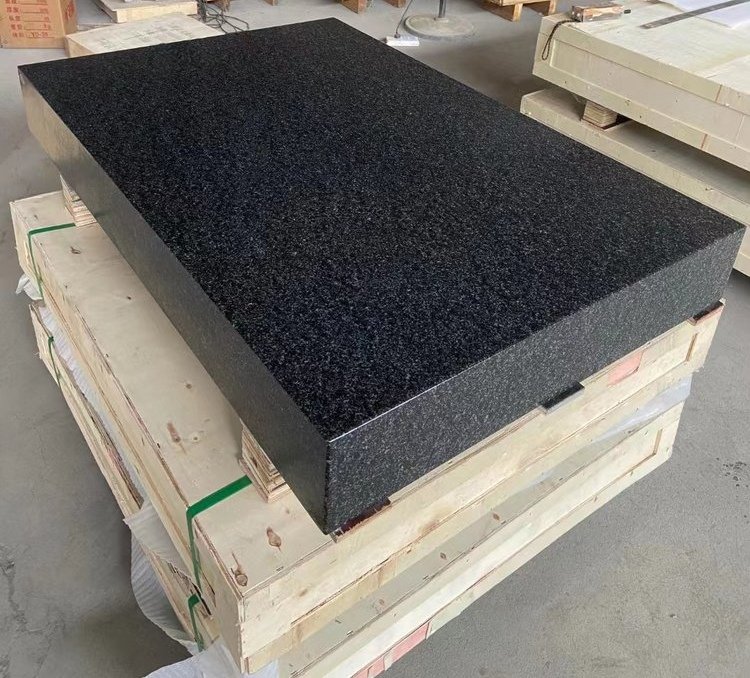

The grinding process of marble platform mainly includes 5 steps

①First, the marble platform to be processed is roughly ground, and rough grinding is to control the thickness and flat of the marble components within the standard.

②The marble platform that has been roughly ground is further semi-fine ground, and semi-fine grinding can remove deeper scratches to make marble platform achieve the standard flatness.

③Grind the surface of the marble platform, and further precision the flatness of the semi-fine ground surface to achieve a base.

④Grind the marble platform with precision manually to further refine the precision until it meets the required precision.

⑤Polish the marble platform that has reached the standard after fine grinding, and the surface of the polished marble platform is smooth and wear-resistant, with a small value of the plane roughness, ensuring stable precision